-

Conveyor System

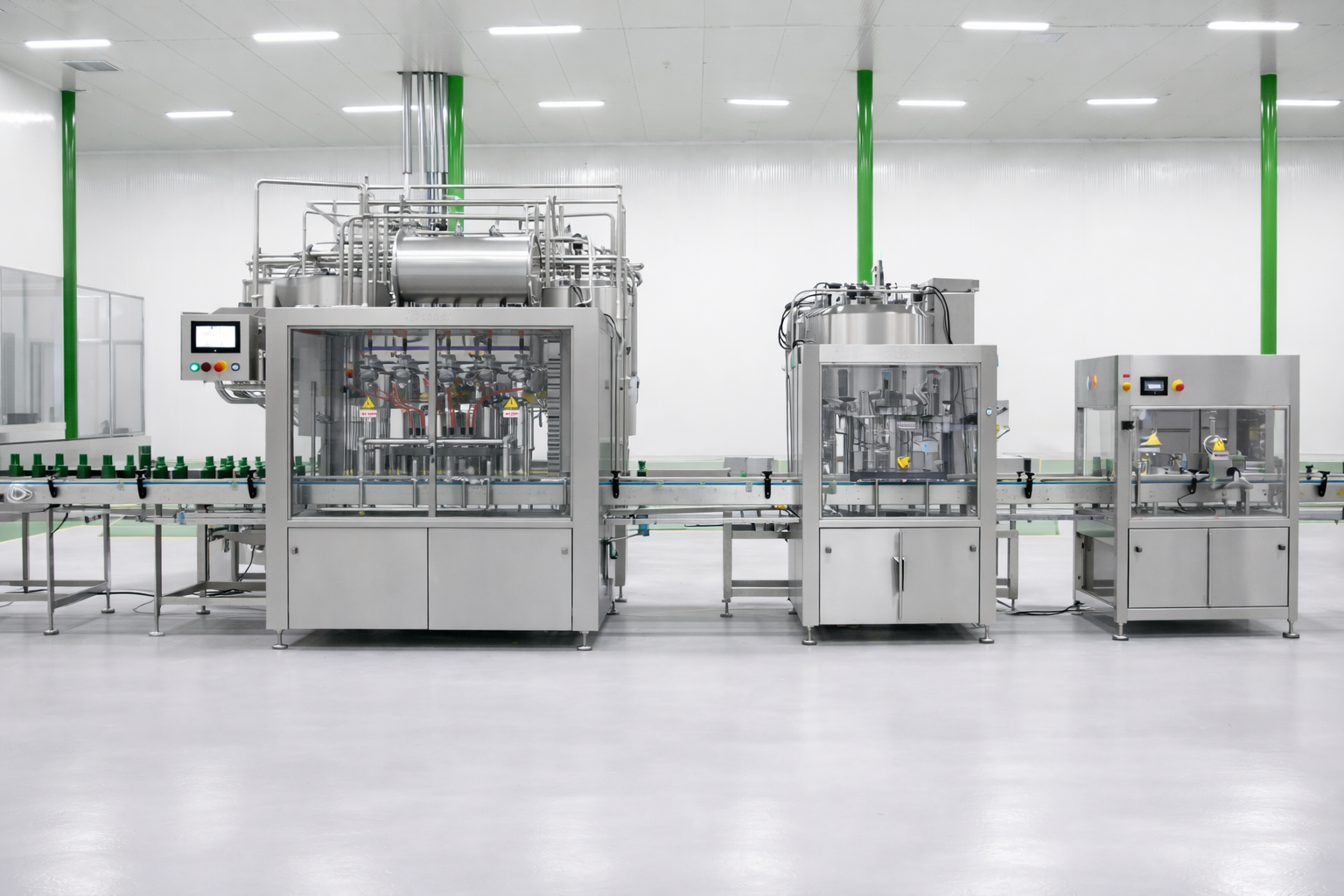

Linear Liquid Filling Line

It offers an advanced solution that optimises your production line and increases efficiency by performing liquid filling, capping and labelling operations at high speed with a linear system.

-

Conveyor System

Rotary Liquid Filling Line

It continuously and rapidly performs liquid filling, cap sealing and labelling operations with a recirculating system, increasing capacity and accelerating the production process. Its compact design saves space.

-

Conveyor System

Linear Powder Filling Line

The linear system, which enables the rapid, precise and continuous filling, capping and labelling of powdered products, optimises production processes and minimises the margin of error.

-

Conveyor System

Linear Tablet Counting Line

Tablet counting lines are integrated packaging solutions that enable tablets and capsules to be counted accurately and filled into bottles, followed by automatic capping and labelling.

ABOUT US

TÜRESAN MACHINERY

TÜRESAN was established to develop machinery, process, and automation systems for industrial production, bringing engineering, manufacturing, and system integration toget- her under one roof as a reliable manufacturing and solution partner.

Serving industries such as food, pharmaceuticals, cosmetics, chemicals, cleaning products, and related sectors, TÜRESAN delivers end-to-end solutions covering every stage—from the design of filling, packaging, and production processes to commissioning and start-up.

Rather than offering standard machines, TÜRESAN follows a project-based approach, tailoring each solution to specific process dynamics, capacity requirements, and operatio- nal needs. Accordingly, all systems are designed and manufactured with a strong focus on high efficiency, long service life, hygiene, precision, and sustainability.

With its strong engineering expertise, modern manufacturing capabilities, and flexible production structure, TÜRESAN positions itself not merely as a machine supplier, but as a long-term business partner. Through comprehensive after-sales technical support, service, and spare parts supply, TÜRESAN ensures the continuity, reliability, and optimization of its customers’ production operations.

Sectors

Food & Beverage

Ayran, Cream Cheese, Yogurt, Honey, Chocolate, Jam, Cream, Olive Oil, Powdered Foods

Medicine

Supplements, Syrup, Nasal Spray, Throat Spray, Vitamins, Tablets, Powdered Medications

Cosmetics

Shampoo, Serum, Gel, Lotion, Body Oil, Cologne, Perfume, Cream, Natural Cosmetics

Chemistry

Vehicle Maintenance Products, Cleaning Products, Paint, Solution, Mineral Oil, Powdered Chemicals

Extensive Export Network

Liqiuid Filling Machines

Liqiuid Filling Machines

Our liquid filling machines portfolio includes flowmeter/volumetric/load cell and various methods depending on the product, enabling the filling of liquid products according to the required capacity and requirements.

Powder Filling Machines

Powder Filling Machines

Our portfolio of powder filling machines includes helical/load cell and various other methods tailored to the product, enabling the filling of powder products according to the required capacity and specifications.

Tablet Counting Machines

Tablet Counting Machines

Our tablet counting machines portfolio includes sensor-based/image processing and various product-specific methods for counting and filling tablet-shaped products according to the required capacity and requirements.

Capping Machines

Capping Machines

Cap sealing machines securely seal the caps of filled bottles or jars at high speed and with precision, ensuring the product’s leak-proof integrity and shelf life.

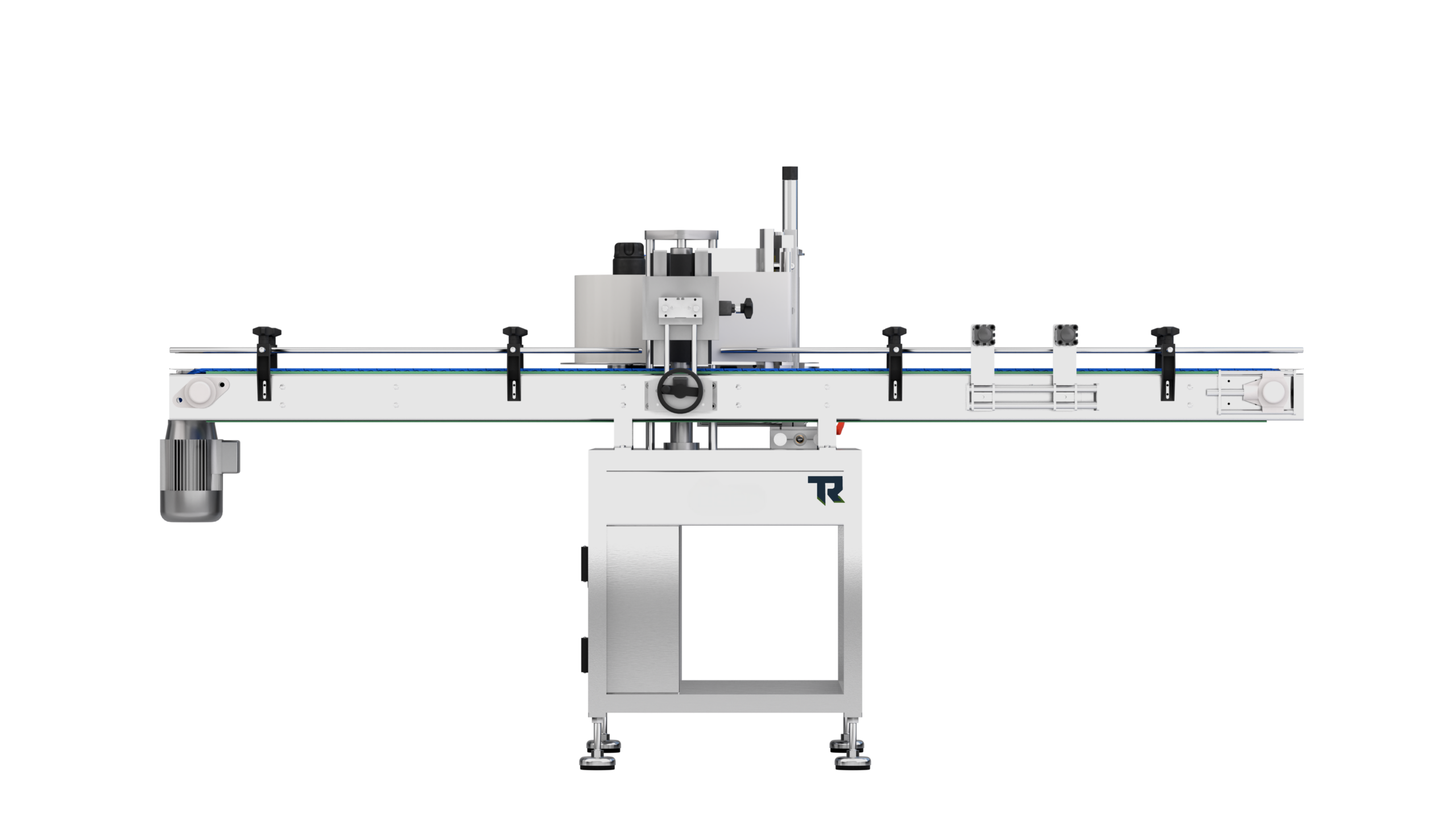

Labelling

Labelling Machine

Our range of labelling machines includes full wrap/single-sided/double-sided/bottom or top labelling and domestic/foreign applicator options, enabling labelling according to the desired capacity and requirements of the product.

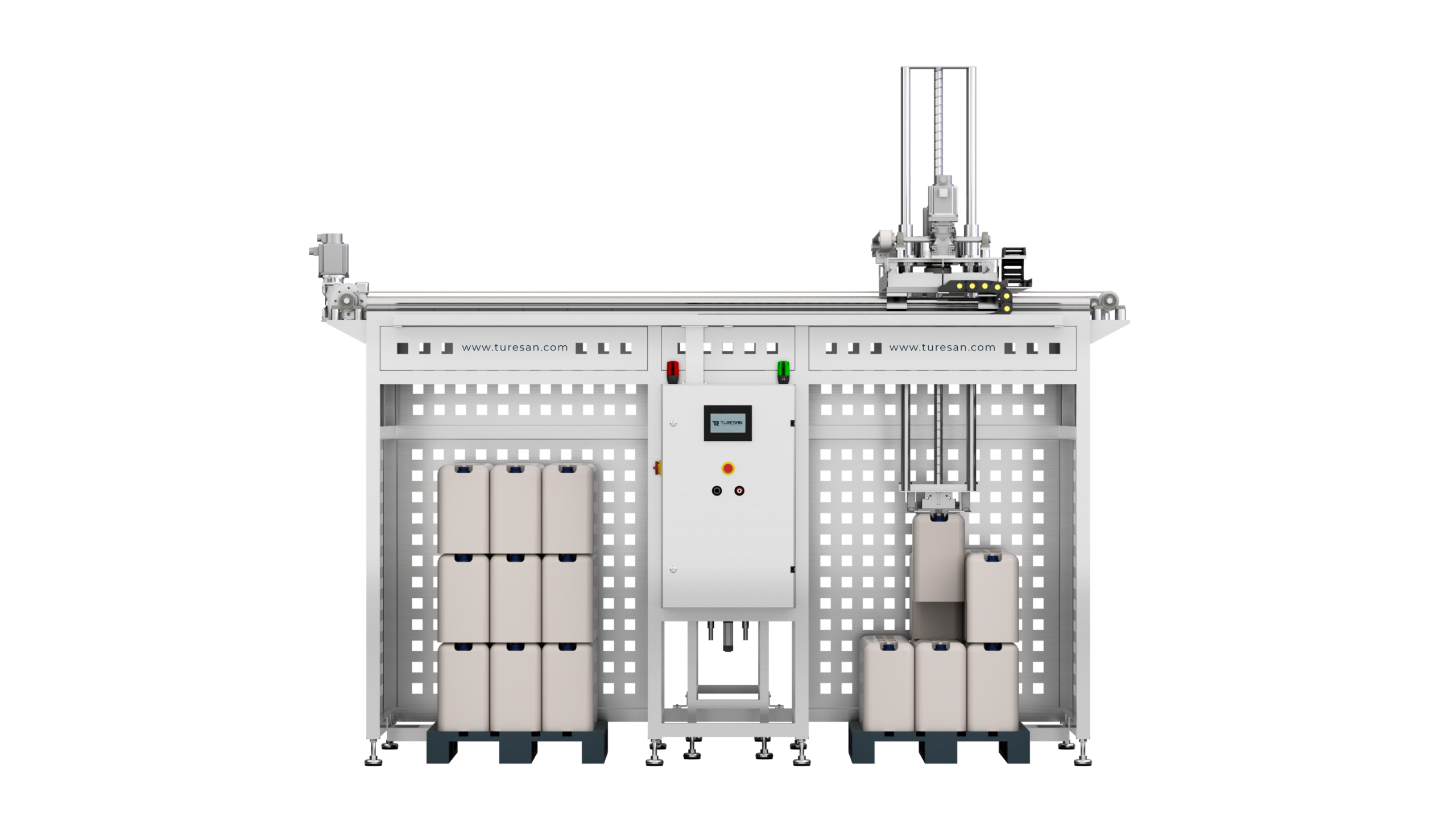

End-of-Line Solutions

End-of-Line Solutions

At the end of the line, machines optimise your production processes with options for grouping, palletising, box opening and product placement according to your specific requirements.

Türesan Machinery Catalog

You can examine in detail the filling, capping and automation machines developed by Türesan with its engineering-focused production approach, along with their specialised solutions for different sectors, technical specifications and application areas, and easily discover the most suitable system for your business.

TÜRESAN CAREER

A career at Türesan is not just a job;

it is being part of production, engineering and development.

Why should you choose Türesan?

Frequently Asked Questions (FAQ)

In this section, we have provided detailed answers to the questions we most frequently receive from our customers regarding our products and services. Topics of interest regarding filling machines, capping systems, conveyor production lines, automation solutions, and special projects are covered in a wide range, from technical specifications to areas of use, production capacity to customisation options. Our aim is to ensure you can quickly and clearly access the information you need when selecting the most appropriate solution for your production process.

This Frequently Asked Questions section not only provides general information but also serves as a guiding resource on important topics such as technical details you may encounter during the investment process, machine selection criteria, production compatibility, hygiene standards, and energy and air requirements. You can also find answers in this section to questions such as which sectors our products are suitable for, which filling systems should be preferred for which product types, and the impact of automation levels on production efficiency.

The feeding tray ensures that empty bottles are transferred to the production line in an orderly manner. This eliminates the need for the operator to place each bottle individually on the conveyor. It provides a personnel cost advantage.

Air cleaning machines clean bottles prior to filling by blowing air into the bottles and removing foreign matter such as dust through a vacuum system. They are commonly used in the food/pharmaceutical industry.

Filling machines fill products at a capacity that cannot be achieved by manual labour. This enables the establishment of a fully automated system capable of filling 20,000 products per hour, thereby reducing production costs. Filling solutions are developed according to the product using liquid filling, powder filling, and tablet counting methods.

Depending on the filling system used, our machines generally operate within a tolerance range of ±0.3% to ±0.5%.

We offer specialised solutions for many sectors requiring filling of liquid, semi-fluid, powder and tablet products, primarily for production in the food, cosmetics, chemical, cleaning, pharmaceutical and industrial sectors.

Capping machines must be designed according to different types of caps. Throat spray caps, glass jar caps, screw caps or flat plastic caps require different cap tightening systems. For this reason, the cap tightening process is carried out using different systems such as gripper/three-ball system/pick & place/flat tightening/screw/press, depending on the cap type and desired capacity.

The cap feeding system ensures that caps are placed onto bottles with the aid of machinery. This is a preparatory step prior to the cap sealing process. Depending on the cap type and desired capacity, the cap feeding process is carried out using elevator/vibration bowl/drum systems. The cap feeding system reduces operational costs.

Labelling machines apply labels to the desired area of packaging with precision, flatness and consistency. Systems are available for full wrap/single-sided/double-sided/bottom or top labelling.

The collection tray facilitates the operator's work by using a tray for products whose production process has been completed. Thus, products coming off the line are held in the collection tray for a certain period of time for secondary packaging processes.

Yes. We offer end-to-end solutions tailored to your needs, including process planning, bottle feeding, bottle cleaning, filling, capping, labelling, collection, grouping, boxing, and palletising.

Yes. The bottle/can/jar/tube form, filling range, nozzle count, cap sealing system and line length can all be custom designed to suit your production requirements.

Yes. We offer solutions suitable for different production capacities, including manual, semi-automatic and fully automatic systems.

We offer installation, commissioning, operator training and after-sales technical support services. Spare parts and service support are also available.

Production time varies depending on the machine type and level of customisation. The net delivery time will be communicated to you once the project details have been finalised.

Yes. The machines we produce are designed and manufactured in accordance with CE standards.

Blogs

Endüstriyel üretimde dolum hattı seçimi, yalnızca makine tercihi değil; ürün kalitesi, üretim kapasitesi ve işletme verimliliğini doğrudan etkileyen stratejik bir karardır. Ürünün viskozitesi, ambalaj tipi, dolum hassasiyeti ve hedeflenen üretim adedi, doğru sistemin belirlenmesinde temel kriterlerdir. TÜRESAN Endüstriyel, lineer ve rotary sistem dolum hatlarını; sıvı, toz ve granül ürünlere özel mühendislik çözümleriyle tasarlar. Konveyörlü yapılar, servo …

Gıda üretiminde hijyen, sürdürülebilir kalite ve yasal uygunluk açısından kritik öneme sahiptir. Dolum ve paketleme süreçlerinde kullanılan makinelerin, ürünle temas eden tüm yüzeylerinin hijyen standartlarına uygun olması gerekir. TÜRESAN gıda sektörüne yönelik dolum makinelerini; AISI 304 ve AISI 316L paslanmaz çelik konstrüksiyon, kolay temizlenebilir dolum hazneleri ve C.I.P. uyumlu sistemlerle geliştirir. Süt, içecek, sos, bal, granül …

İlaç sektöründe üretim süreçleri; mikron seviyesinde hassasiyet, tekrarlanabilirlik ve tam kontrol gerektirir. Tablet, kapsül ve sıvı farmasötik ürünlerde hata payının minimumda tutulması kritik bir gerekliliktir. TÜRESAN, ilaç sektörüne özel olarak geliştirdiği tablet sayma ve sıvı dolum sistemlerinde vibrasyonlu sayma teknolojisi ve servo kontrollü dolum çözümleri sunar. Şişe, blister ve kutu ambalajlara tam uyumlu sistemler, üretim hattında …