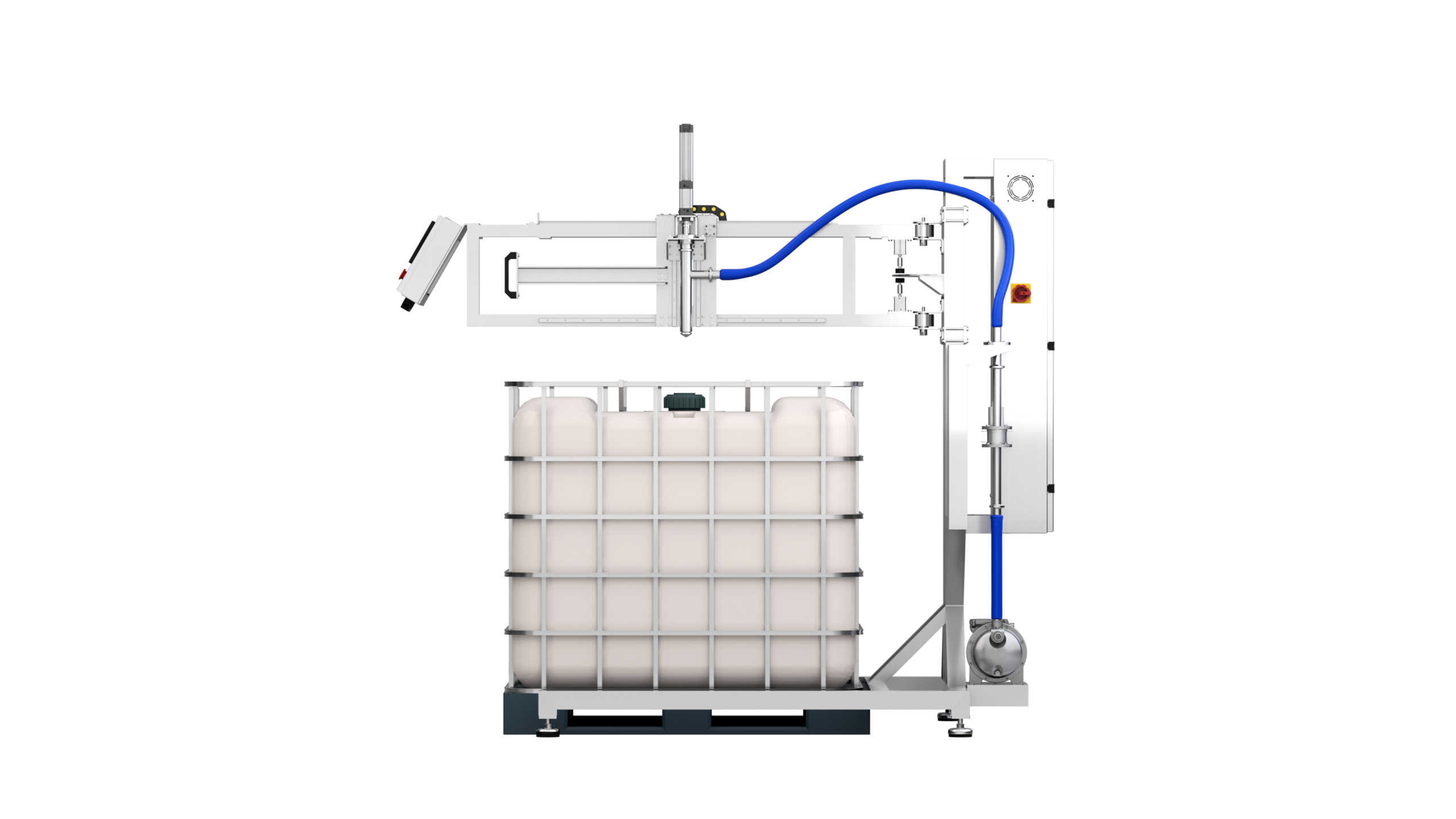

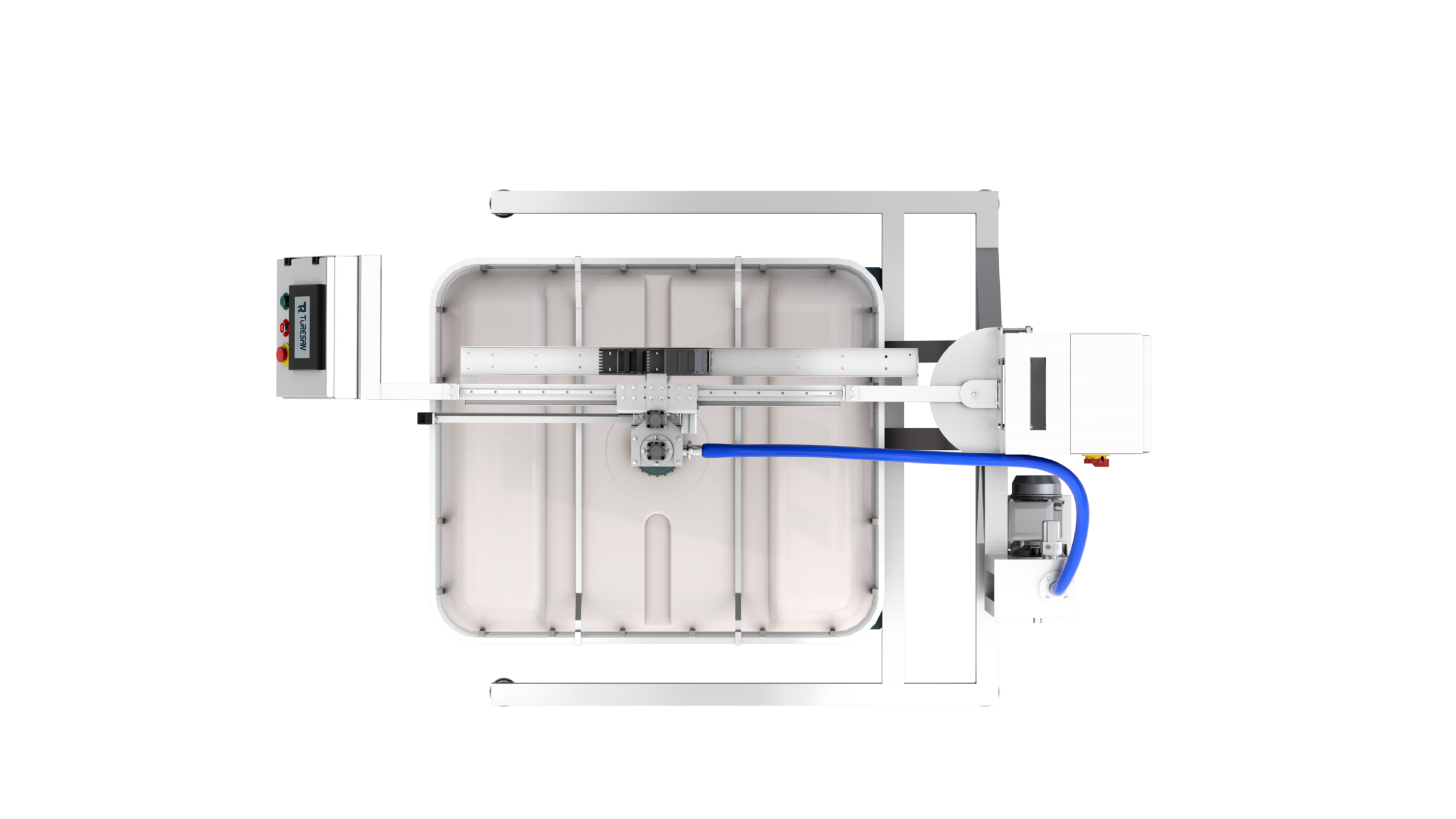

Drum Filling Machine

| Feature | Value |

|---|---|

| System | Manual |

| Filling System | Flowmeter / Loadcell |

| Base Frame | AISI 304 Stainless Steel Frame, Product Contact Surfaces AISI 316L Stainless Steel |

| Sealing System | Ultrasonic / Heat |

| Number of Nozzles | 1 |

| Filling Range | 200-1000 Liters |

| Filling Accuracy | ± %0,5 |

| Capacity | Varies depending on drum tank and product viscosity |

| Electrical Requirement | 380 V, 50 Hz, 3 Phase |

| Air Requirement | 6-8 Bar |

Drum Filling Machine

The drum filling machine is a manual filling solution designed for the controlled and safe filling of high-volume liquid products into drums and large containers. Thanks to the flow meter and load cell-supported filling system, the filling quantity is precisely controlled, minimising product loss with a filling accuracy of ±0.5%. The use of AISI 304 stainless steel chassis and AISI 316L stainless steel on surfaces in contact with the product ensures that the machine offers a hygienic and durable structure for food, chemical and industrial liquids. Adaptable to different packaging and sealing requirements with an ultrasonic or temperature-controlled sealing system, the barrel filling machine offers flexible use in the 200–1000 litre filling range with its single nozzle design. The system, which has a variable capacity depending on the barrel tank shape and product viscosity, is an ideal filling solution for stable and long-term industrial use with a 380 V, 50 Hz, 3-phase electrical infrastructure and 6–8 bar air requirement.