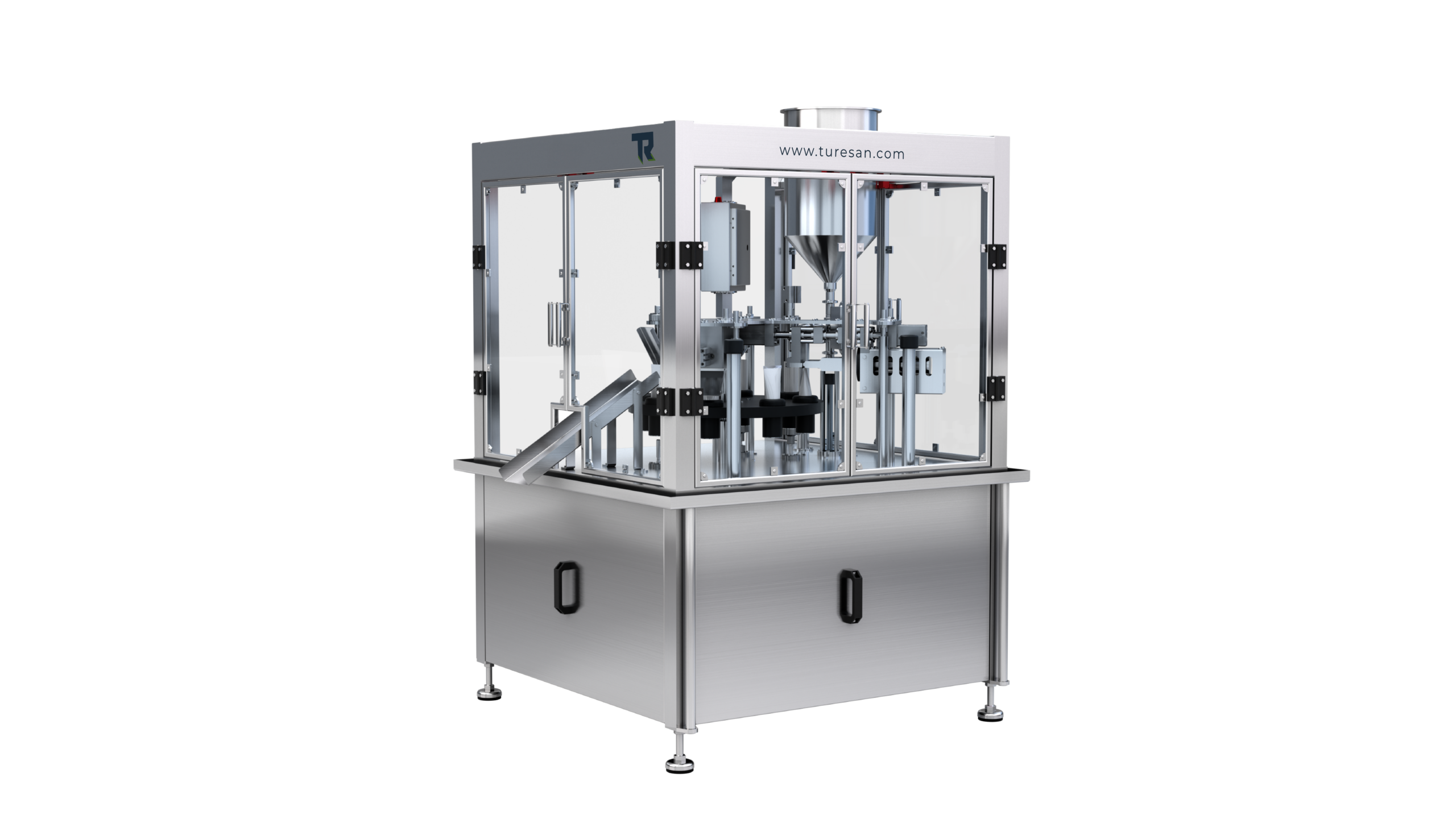

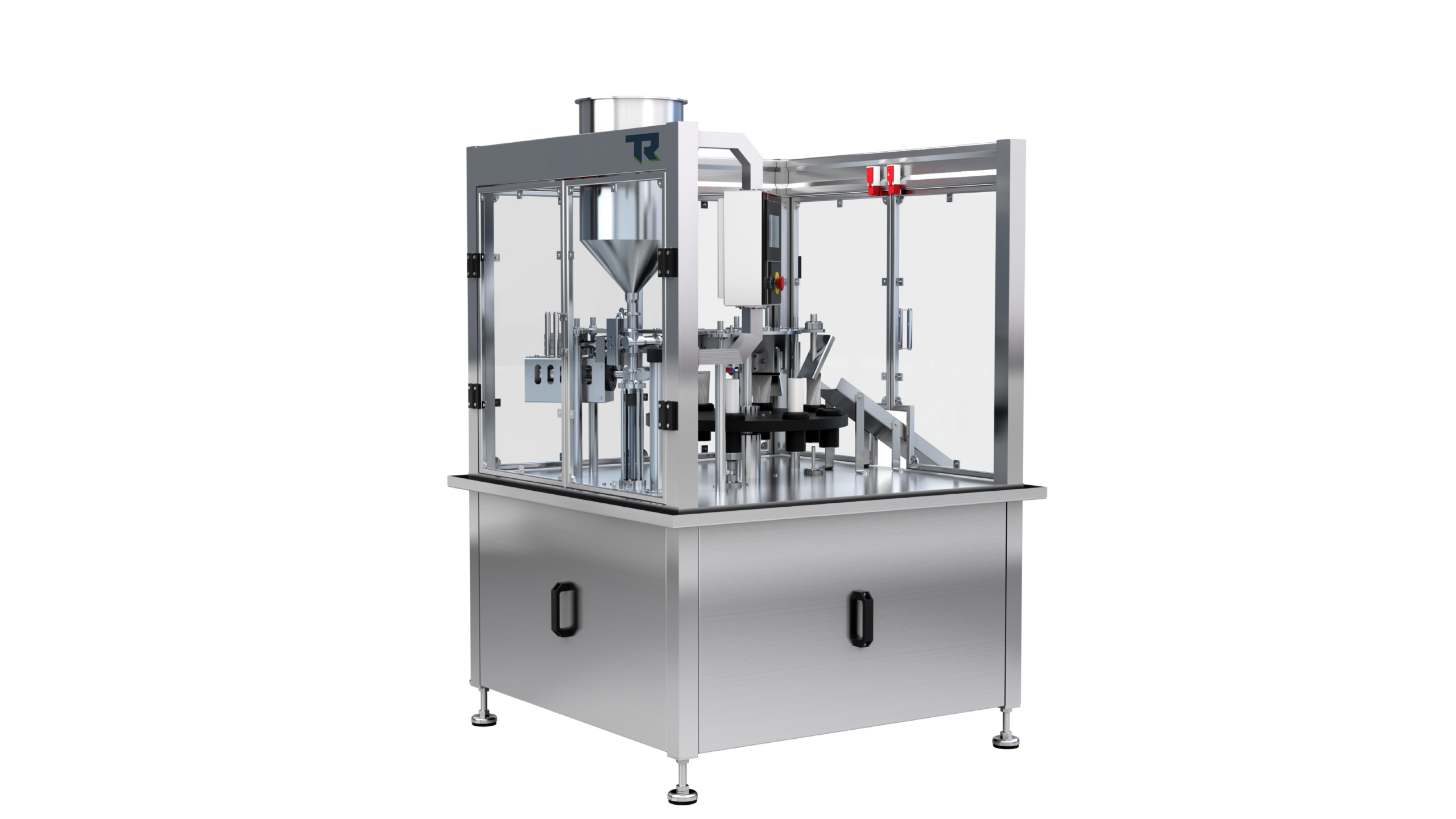

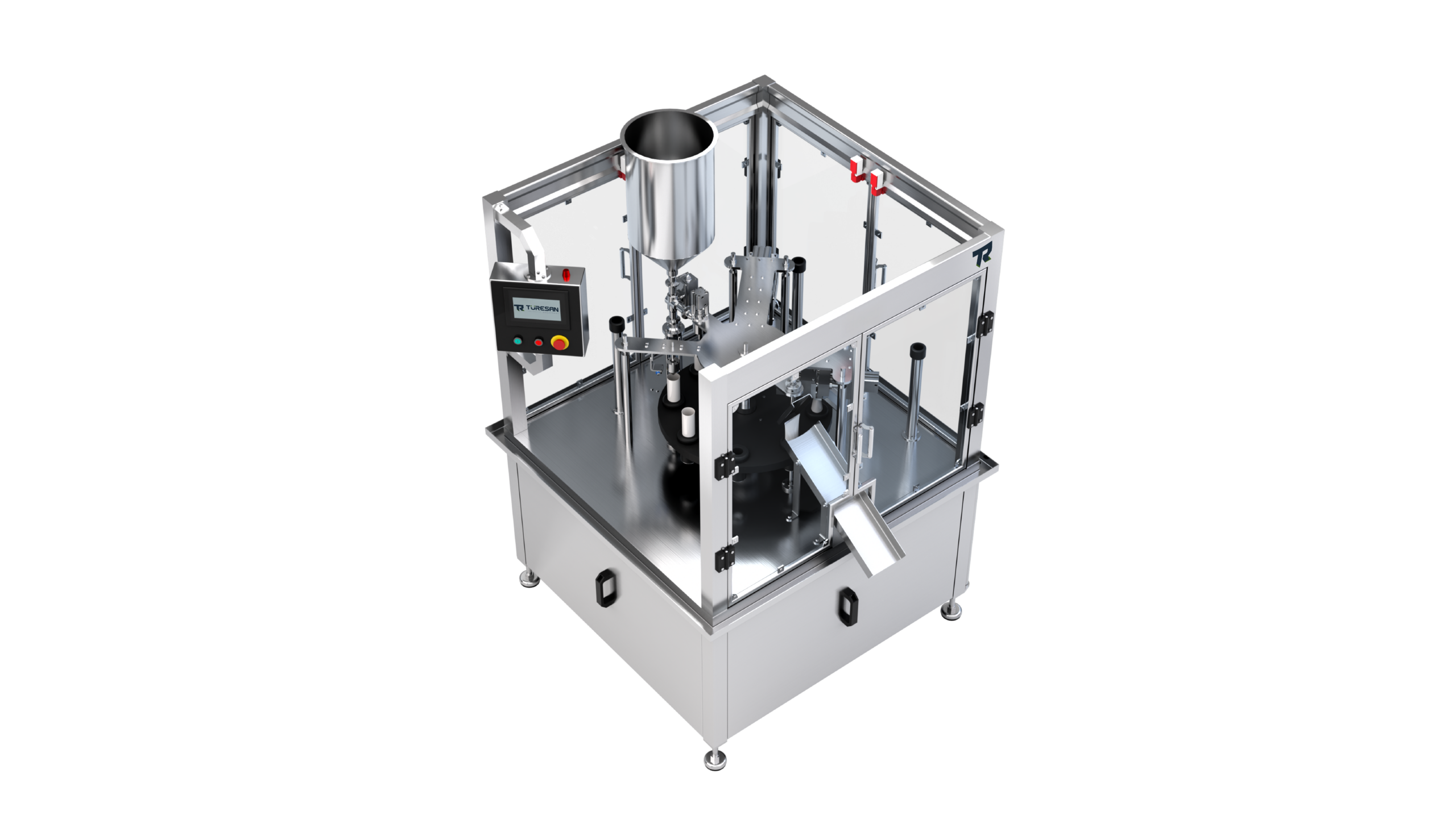

Tube Filling Machine

| Feature | Value |

|---|---|

| System | Rotary |

| Filling System | Volumetric |

| Sealing System | Ultrasonic/Heat |

| Base Frame | AISI 304 Stainless Steel Frame, The interacting surfaces with the product are AISI 316L Stainless Steel |

| Balance Tank | Level Controlled |

| Number of Nozzles | 1 |

| Filling Range | 30 – 300ml |

| Filling Accuracy | ± %0,3 |

| Capacity | Varies depending on tube form, number of nozzles, and product viscosity |

| Electrical Requirement | 380 V, 50 Hz, 3 Phase |

| Air Requirement | 6-8 Bar Servo Controlled Volumetric Filling System C.I.P. System, Tube Presence/Absence and Pressure Sensors |

Tube Filling Machine

The tube filling machine is an industrial filling solution developed by Türesan Engineering for the precise, hygienic and controlled filling of semi-fluid products such as creams, gels, lotions and similar items into tube packaging. Thanks to its rotary system structure and servo-controlled volumetric filling system, filling operations are performed in a stable and repeatable manner, while ultrasonic or temperature-controlled sealing systems ensure strong and reliable leak-proof sealing during the tube closure process.

The AISI 304 stainless steel chassis and AISI 316L stainless steel surfaces that come into contact with the product offer hygienic, durable and safe use in accordance with hygiene standards for the cosmetics, food and chemical industries. With a wide filling range and high filling accuracy, the system easily adapts to different tube shapes and product viscosities. It provides hygienic cleaning and uninterrupted production with a C.I.P. system and a level-controlled bulk balance tank.

The tube filling machine, with tube presence/absence and pressure sensors to enhance process safety, is an ideal solution for industrial production lines requiring high efficiency, thanks to its low maintenance requirements and user-friendly control panel.