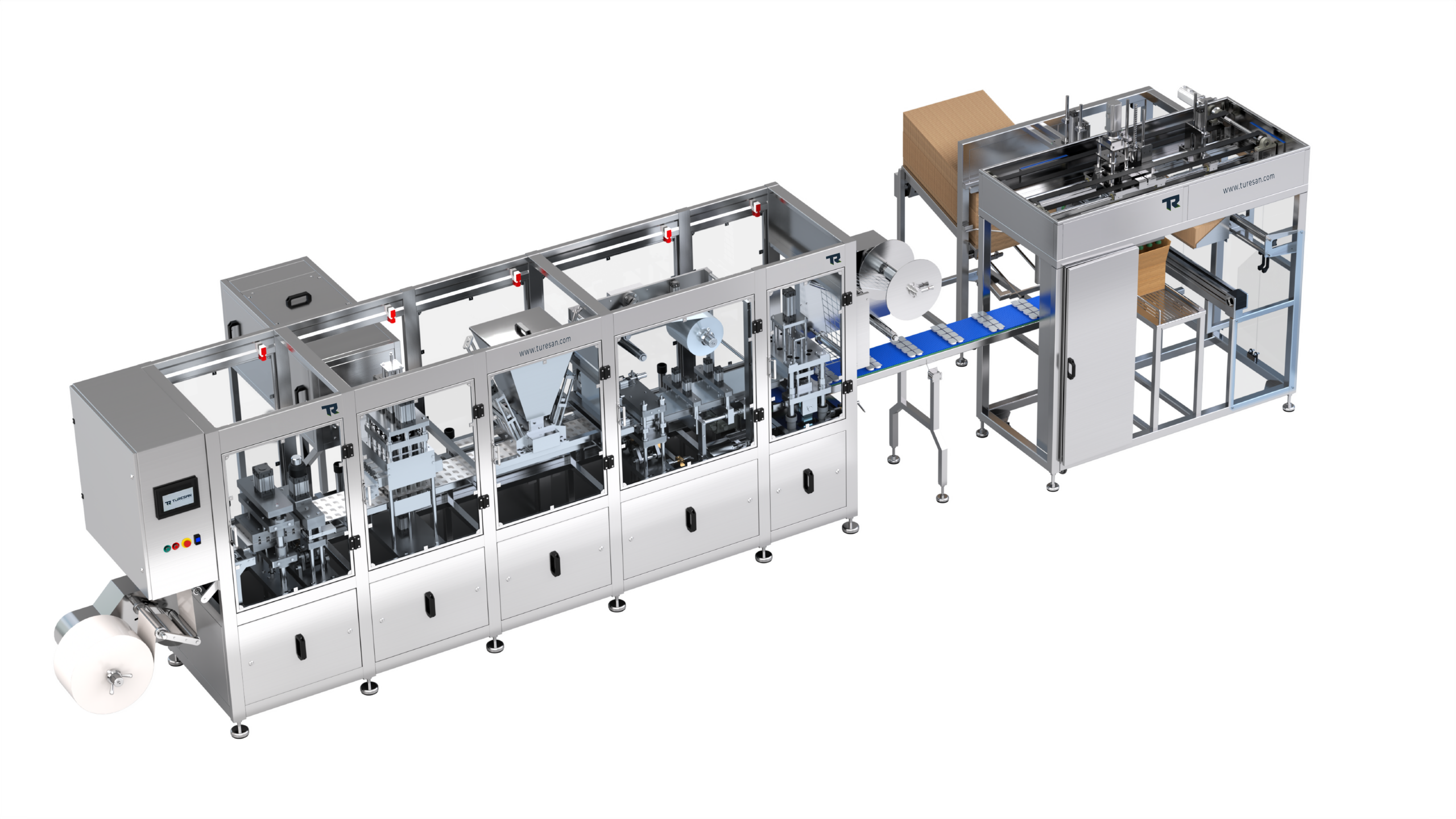

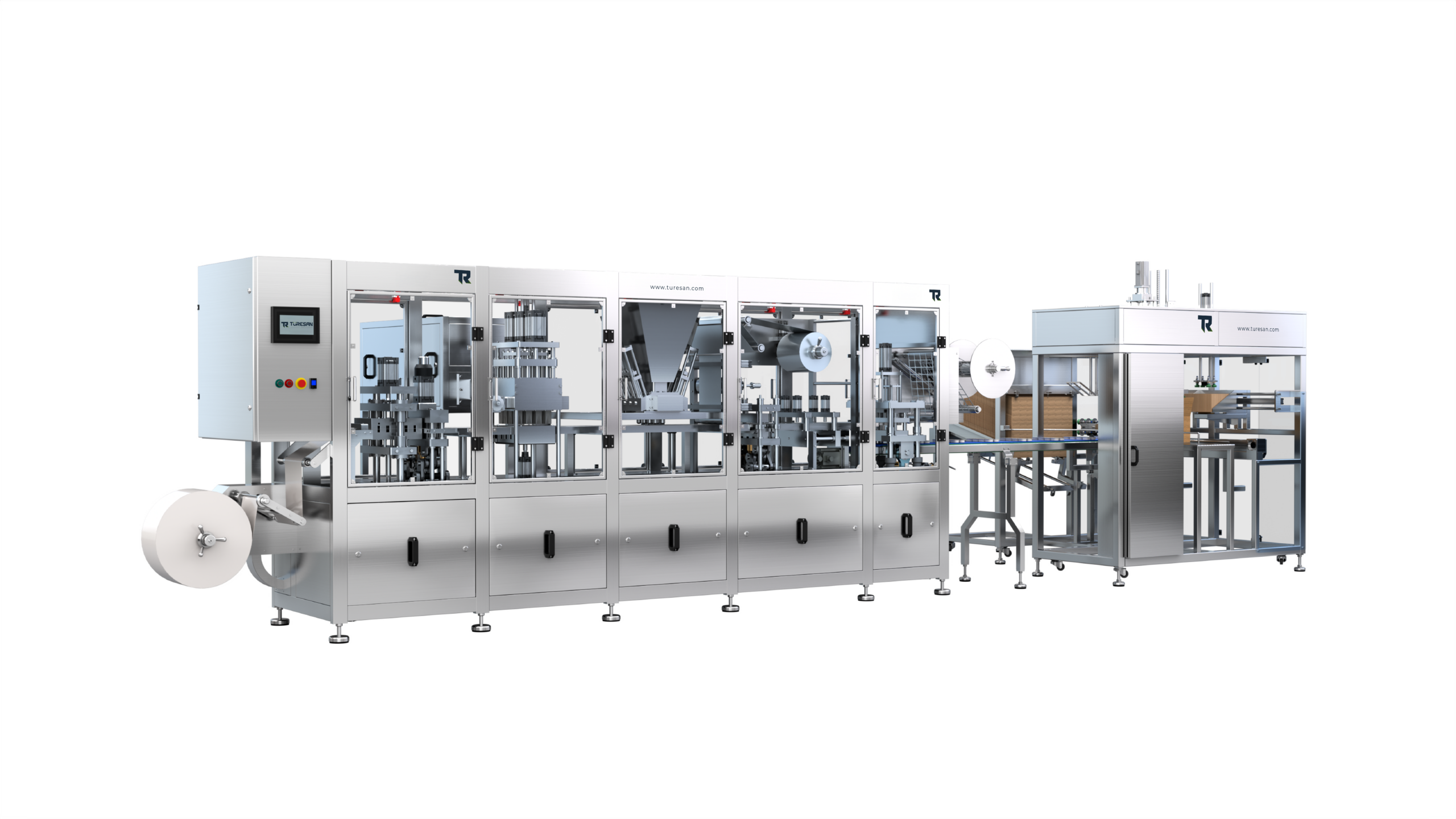

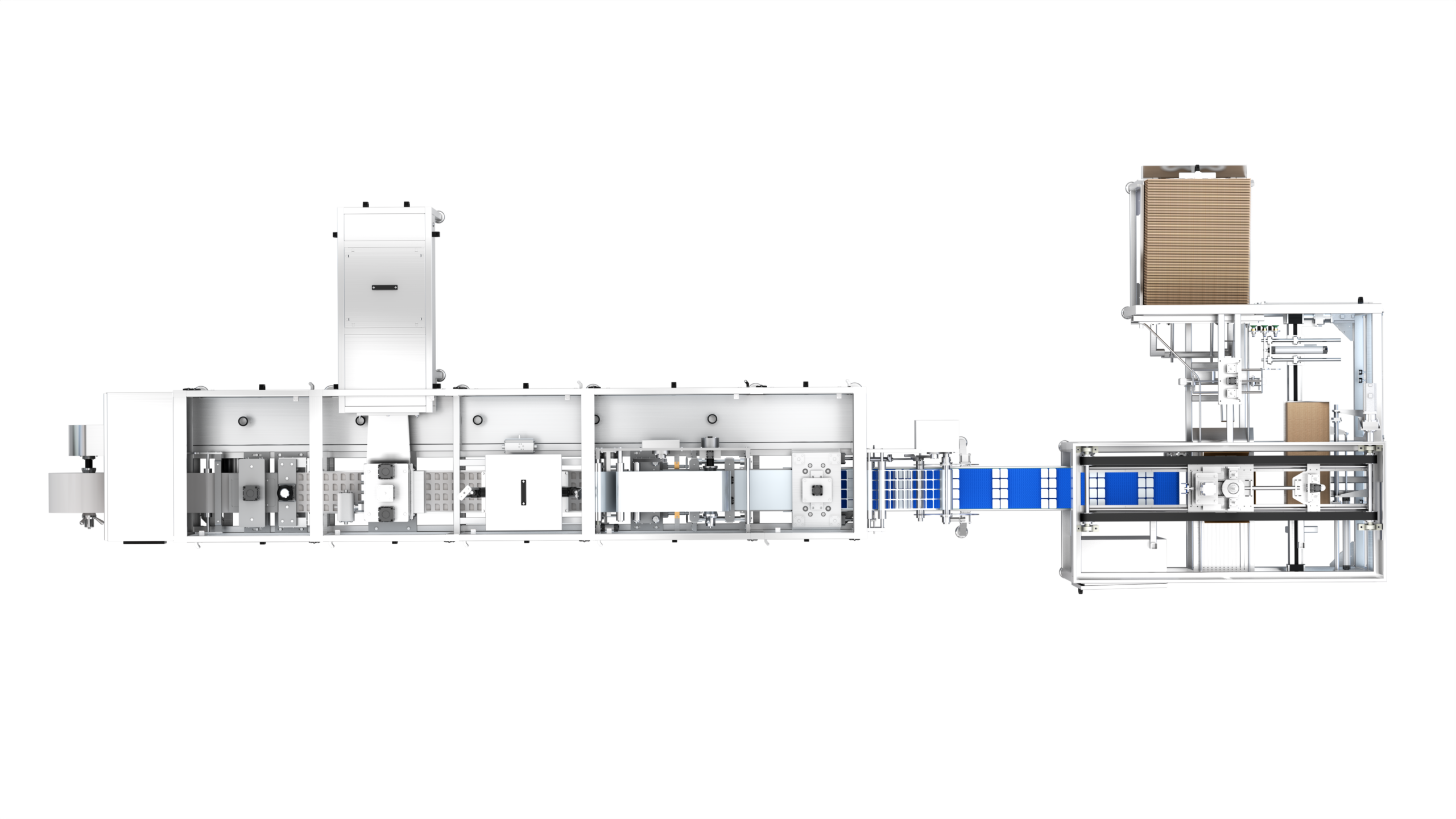

Thermoforming Machine

| Feature | Value |

|---|---|

| System | Linear |

| Filling System | Volumetric |

| Base Frame | AISI 304 Stainless Steel Frame, The interacting surfaces with the product are AISI 316L Stainless Steel |

| Balance Tank | Seviye Kontrollü, C.I.P. Toplu |

| Number of Nozzles | 1 – 20 |

| Filling Range | 10 – 1000ml |

| Servo Motor Driven Systems | Stepper Drive |

| Filling Accuracy | + %0,5 |

| Capacity | Varies depending on packaging form, number of nozzles, and product viscosity |

| Electrical Requirement | 380 V, 50 Hz, 3 Phase |

| Bottom Film | PVC, PS, PET |

| Top Film | AL, AL+OPP |

| Air Requirement: | 6-8 Bar Pressure Sensor, Sterile Positive Air HEPA Filter |

Thermoforming Machine

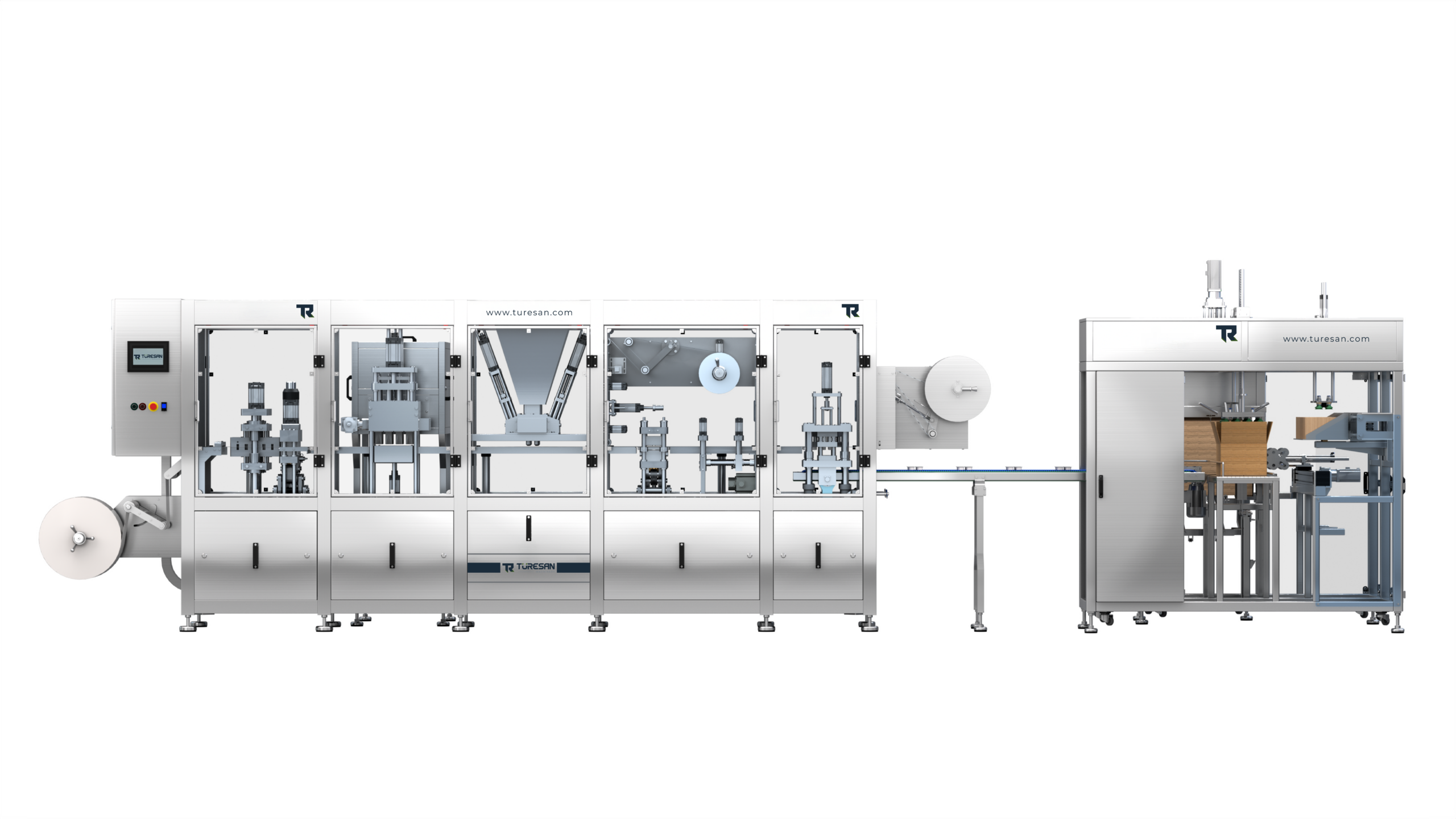

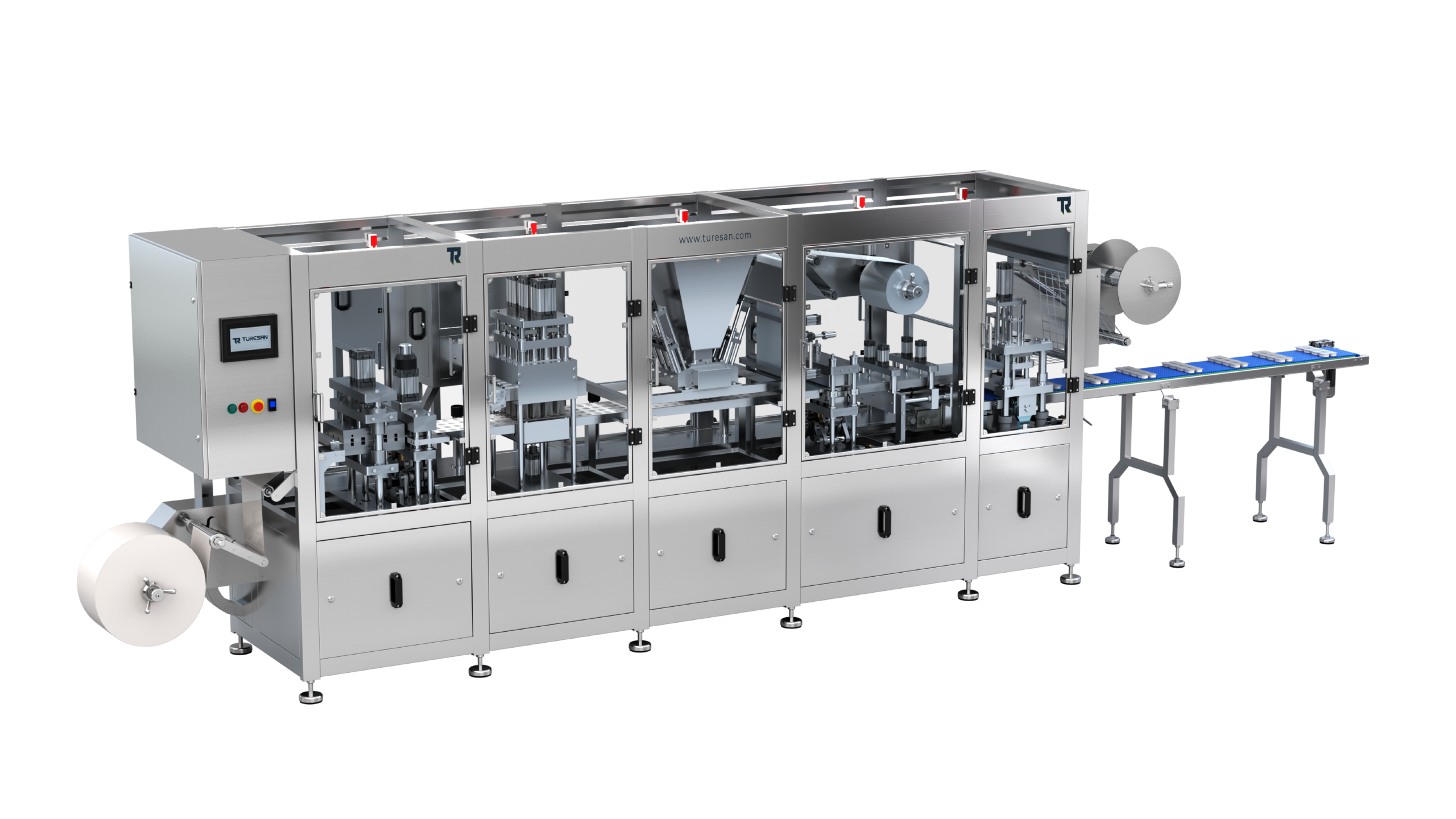

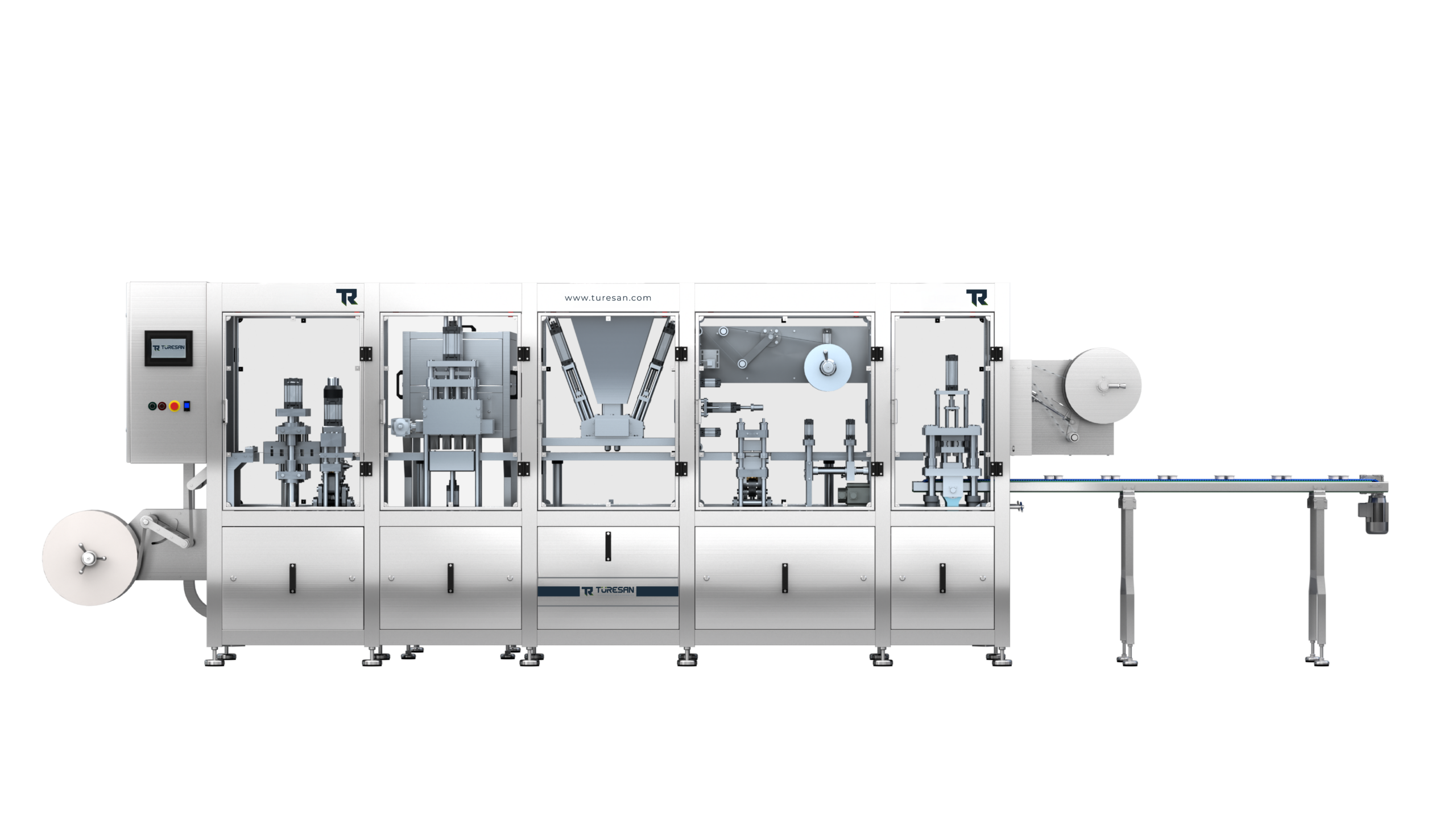

The thermoforming machine is an industrial packaging solution developed by Türesan Engineering for the hygienic, precise and controlled filling of liquid and semi-fluid products into thermoformed packaging. Thanks to its linear system structure and servo-controlled volumetric filling system, stable and repeatable filling results are achieved with different product viscosities, while the AISI 304 stainless steel chassis and AISI 316L stainless steel surfaces that come into contact with the product offer hygienic standards, long-lasting and safe use for the food, chemical and medical sectors.

The system, which adapts to a wide range of nozzle numbers and filling ranges, increases production efficiency by precisely controlling packaging progression with its step-motor-driven structure. The thermoforming machine meets different packaging needs with PVC, PS and PET bottom film options and Al and Al+OPP top film compatibility. It is supported by optional features such as drawer foil feeding and automatic date coding system, tray, foil and lid presence -absence sensors, UV-C lid sterilisation, C.I.P. system, sterile positive air HEPA filter, and pressure sensor, making it an ideal solution for high-capacity, hygiene-focused production lines.