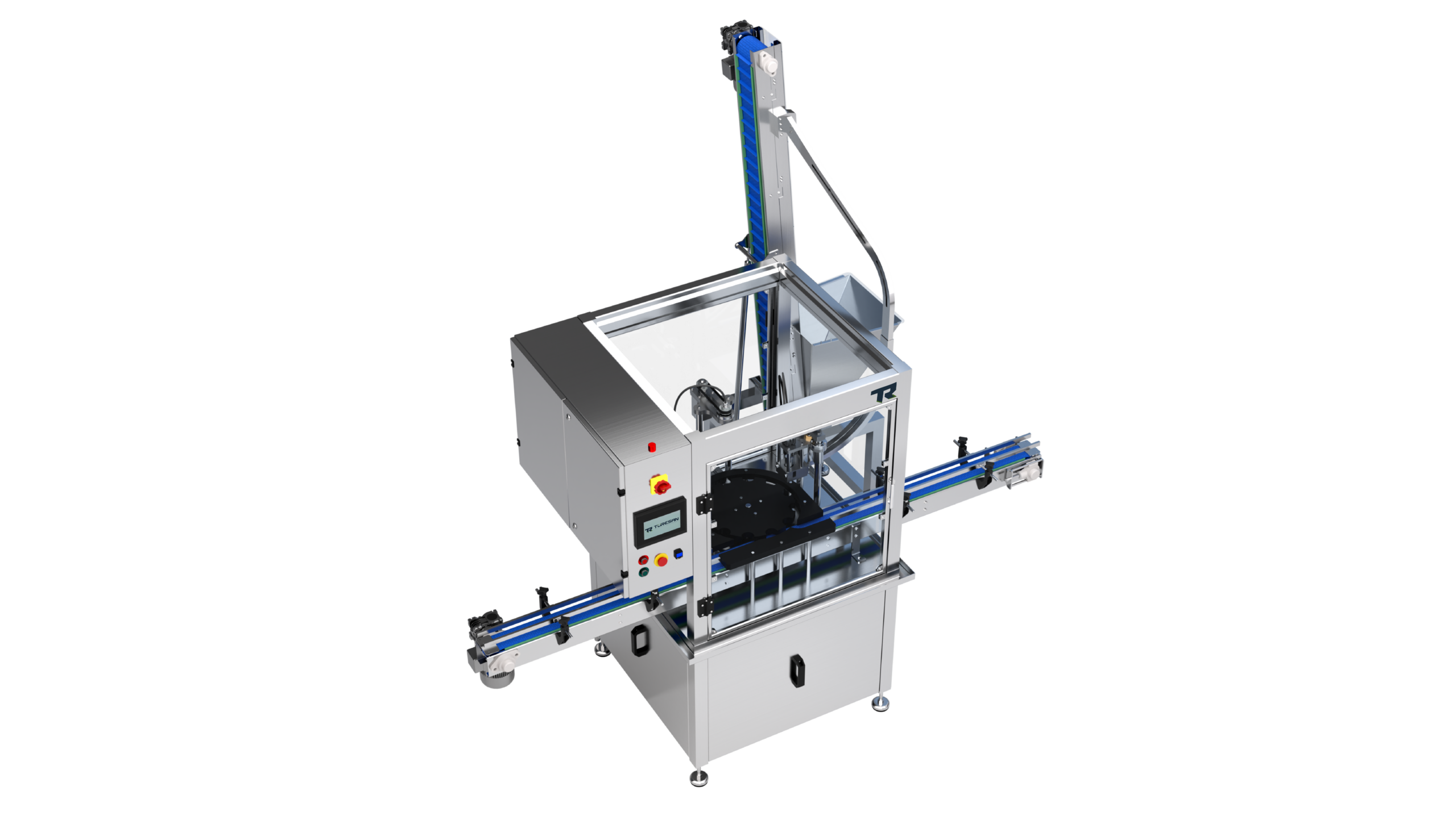

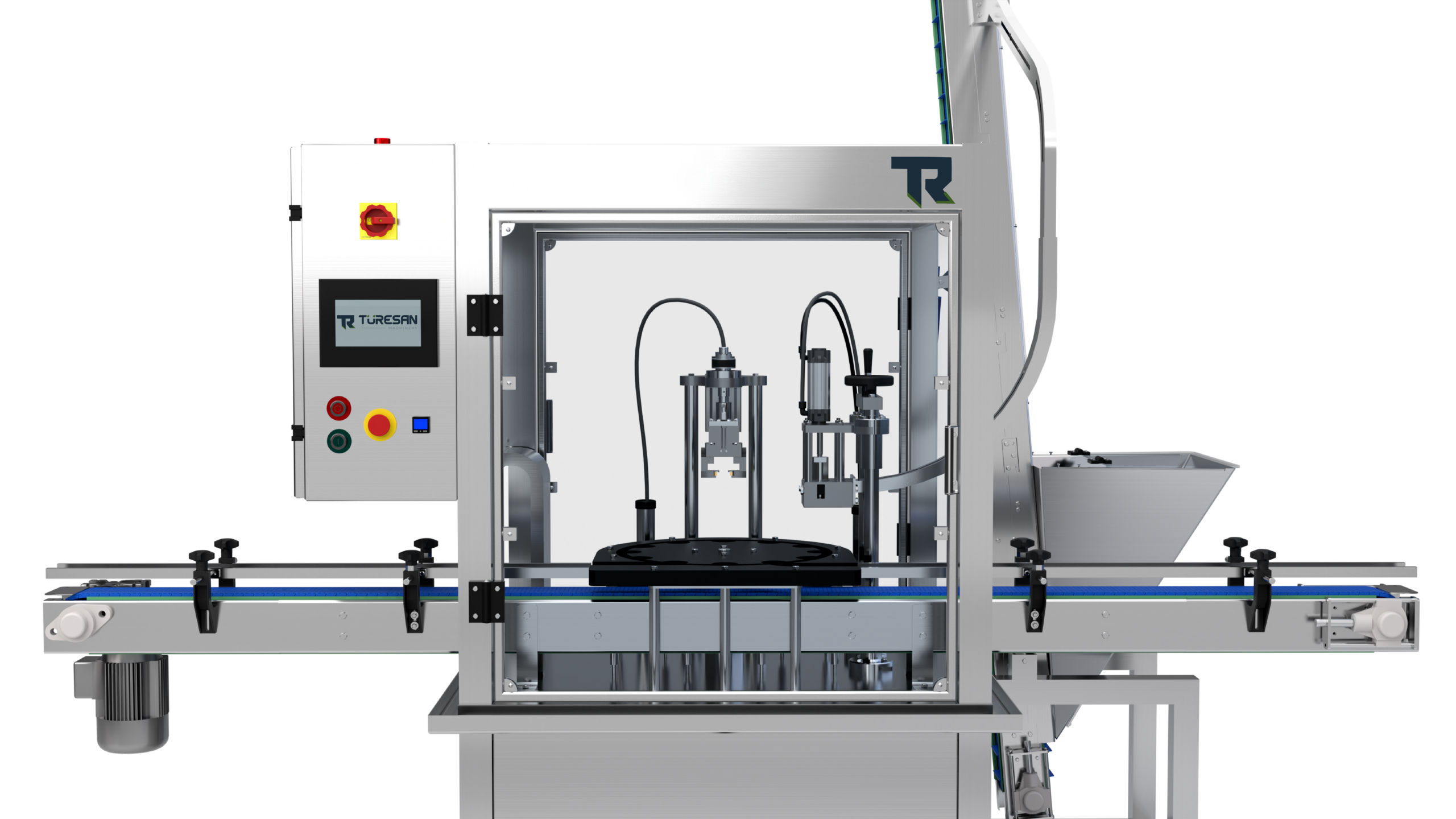

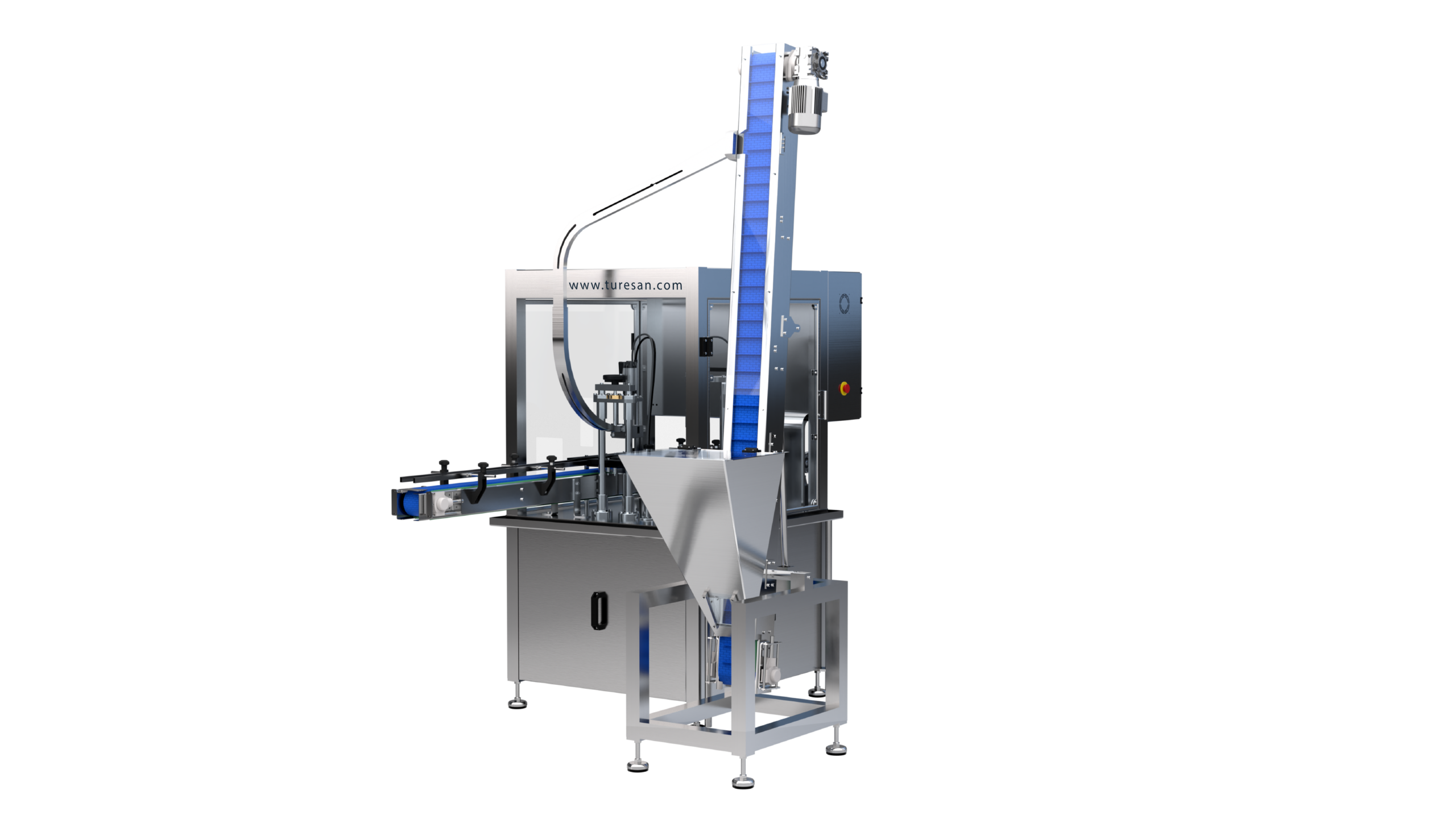

Rotary System Capping Machine

| Feature | Value |

|---|---|

| System | Rotary |

| Base Frame | AISI 304 /AISI 316L Stainless Steel Frame |

| Capping Drive System | Servo Torque / Asynchronous Motor / Mechanical Torque / Air Motor |

| Capping System | Gripper / Üç Top Sistemli / Pick&Place / Düz Sıkma / Sıvama / Press |

| Cap Feeding | Elevator / Vibratory Bowl / Rotary Table |

| Electrical Requirement | 380 V, 50 Hz, 3 Phase |

| Air Requirement | 6-8 Bar Inlet and Outlet Line Full Sensors |

Rotary System Capping Machine

The Rotary System Lid Closing Machine is a professional closing solution designed for high-capacity and mass production lines, operating on the principle of circular motion. It offers hygiene, durability, and long-term use thanks to its AISI 304 stainless steel frame and the use of AISI 316L stainless steel on surfaces in contact with the product. It fully adapts to different cap types and production needs with servo torque, asynchronous motor, mechanical torque or pneumatic motor cap sealing drive systems. It performs precise sealing on plastic, metal and special caps thanks to gripper, three-ball system, pick & place, flat clamping, smearing and press sealing options. Continuous and stable production is supported by elevator, vibrating bowl or drum system alternatives as the cap feeding unit. Operating with a 380 V, 50 Hz, 3-phase electrical infrastructure and 6–8 bar air requirement, the rotary cap closing machine offers controlled, safe and highly efficient closing performance thanks to its inlet and outlet line full sensors.