Conveyor System Rotary Liquid Filling Machine

| Feature | Value |

|---|---|

| System | Rotary |

| Filling System | Volumetric / Flowmeter / Load Cell / Level-Controlled |

| Base Frame | : AISI 304 Stainless Steel Frame, Product-contact surfaces made of AISI 316L Stainless Steel |

| Balance Tank | Level-controlled, C.I.P. |

| Number of Nozzles | 1 – 4 |

| Filling Range | 20 – 300ml / 100 – 1000ml / 250 – 2500ml |

| Filling Accuracy | ± %0,3 |

| Capping System | Gripper / Three Ball System / Pick & Place / Flat Clampin / Screwing / Press |

| Capping Drive System | Servo Torque / Asynchronous Motor / Mechanical Torque / Air Motor |

| Cap Feeding | Elevator / Vibratory Bowl / Rotary Table |

| Capacity | Varies depending on bottle shape, number of nozzles, and product viscosity. |

| Electrical Requirements | 380 V, 50 Hz, 3 Phase |

| Compressed Air Requirement | 6-8 Bar Servo controlled nozzle movement speed and position adjustable via screen Servo controlled volumetric filling system speed and weight adjustable via screen |

Conveyor System Rotary Liquid Filling Machine

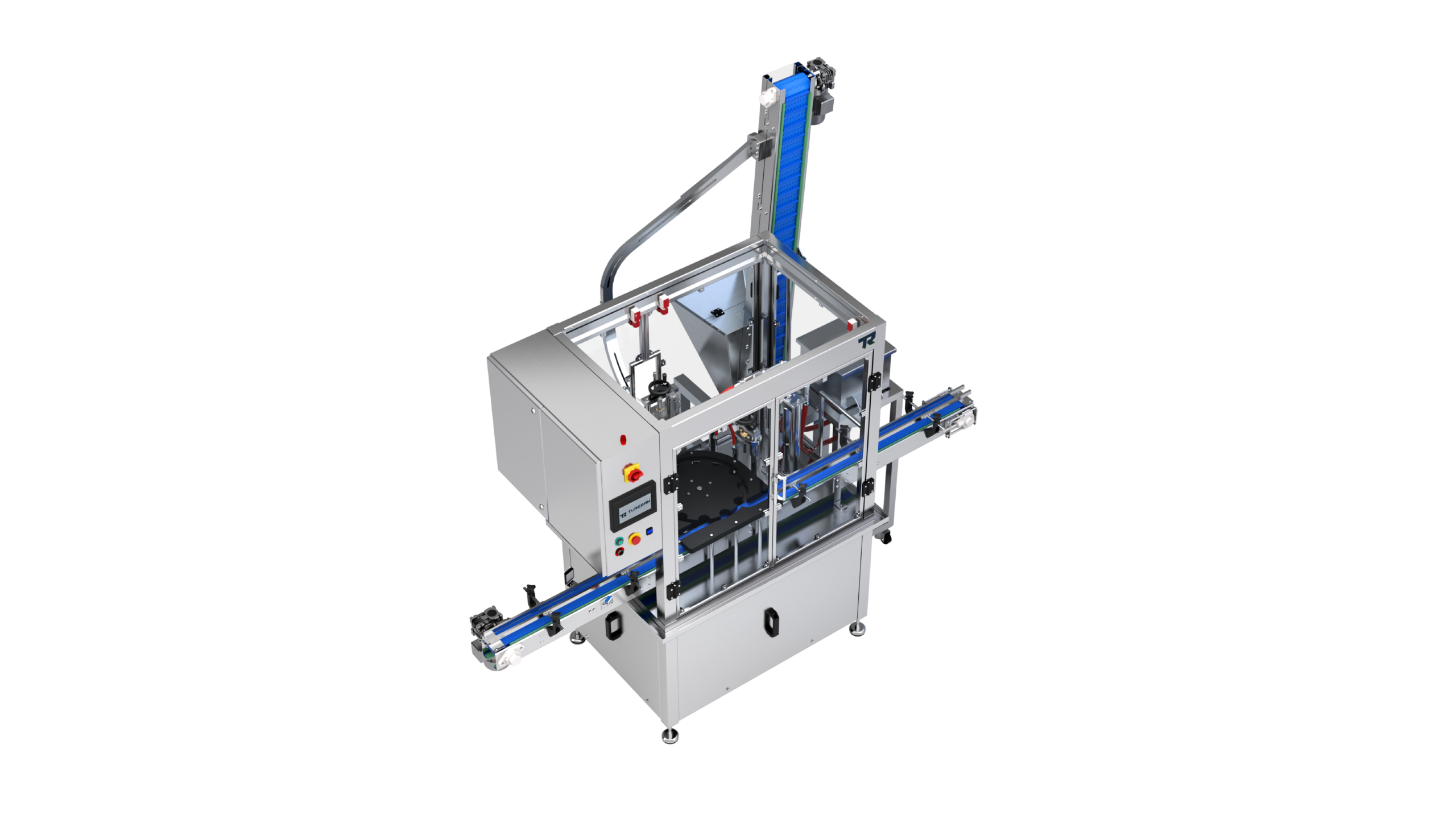

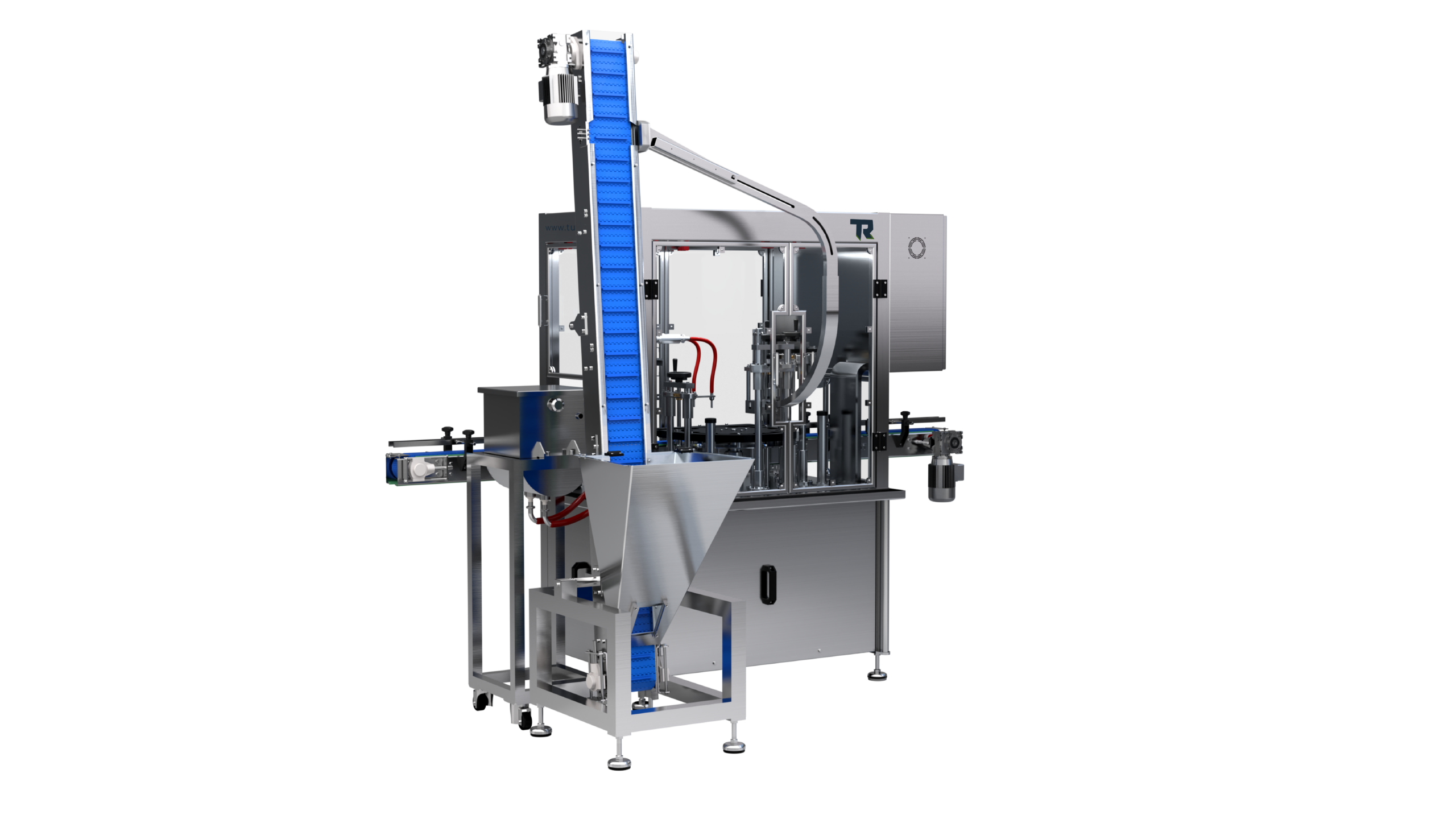

The conveyor-based rotary liquid filling machine is an industrial solution developed for high-capacity filling lines requiring continuous production. Thanks to its rotary system structure, filling, capping, and cap feeding processes operate synchronously, increasing production speed and efficiency.

The servo-controlled nozzle movement system, with speed and position adjustable from the screen, provides precise adaptation to different packaging heights; while the servo-controlled volumetric filling system, with speed and weight adjustable via the operator panel, offers high filling accuracy and repeatability. Volumetric, flowmeter, load cell, and level-controlled filling options provide flexible adaptation to different product viscosities and packaging types.

The AISI 304 stainless steel chassis and AISI 316L stainless steel surfaces that come into contact with the product offer hygienic, durable and safe use in accordance with hygiene standards for the food, chemical and cosmetics industries. Servo-torque, mechanical-torque or asynchronous motor-driven lid closing systems ensure precise tightening for different lid types, while elevator, vibration bowl and drum lid feeding systems contribute to uninterrupted production line operation.

Line-full sensors positioned on the inlet and outlet lines continuously monitor product flow, enhancing production safety. With its modular design, user-friendly control panel, and low maintenance requirements, the rotary liquid filling machine is an ideal filling solution for high-performance industrial production lines.