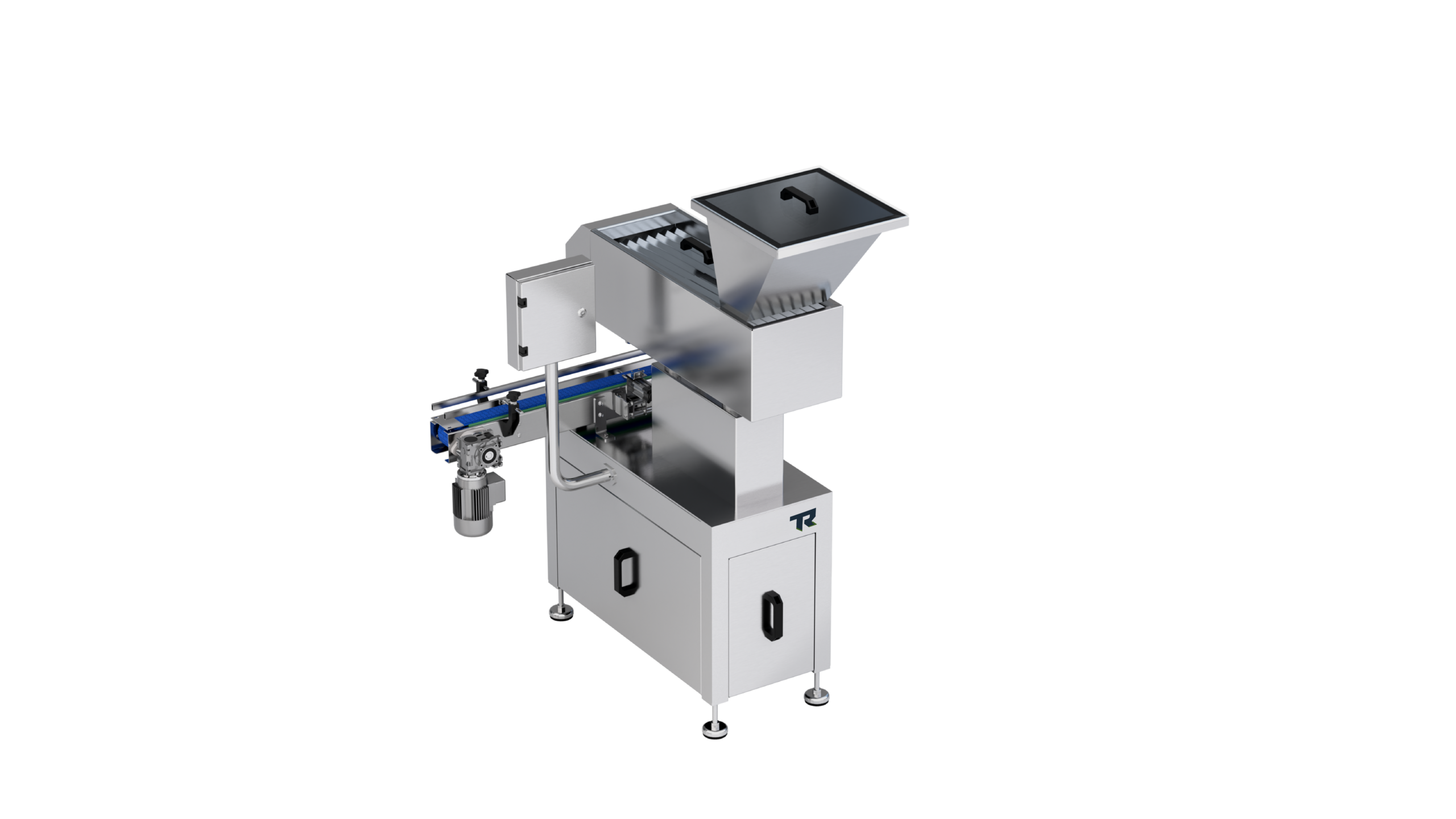

Conveyor System Linear Tablet Counting Machine

| Feature | Value |

|---|---|

| System | Linear |

| Counting System | Vibration |

| Number of Channels | 8 – 24 |

| Base Frame | AISI 304 Stainless Steel Frame, The interacting surfaces with the product are AISI 316L Stainless Steel |

| Number of Nozzles | 1-2 |

| Bottle Range | 15 – 500 ml |

| Counting Accuracy: | ± %0,3 |

| Tablet Diameter | Max. 22 mm |

| Capacity | Varies depending on bottle shape and number of tablets or capsules |

| Electrical Requirement: | 380 V, 50 Hz, 3 Phase |

| Air Requirement | 6-8 Bar Counting Methods for Gummy Products |

Conveyor System Linear Tablet Counting Machine

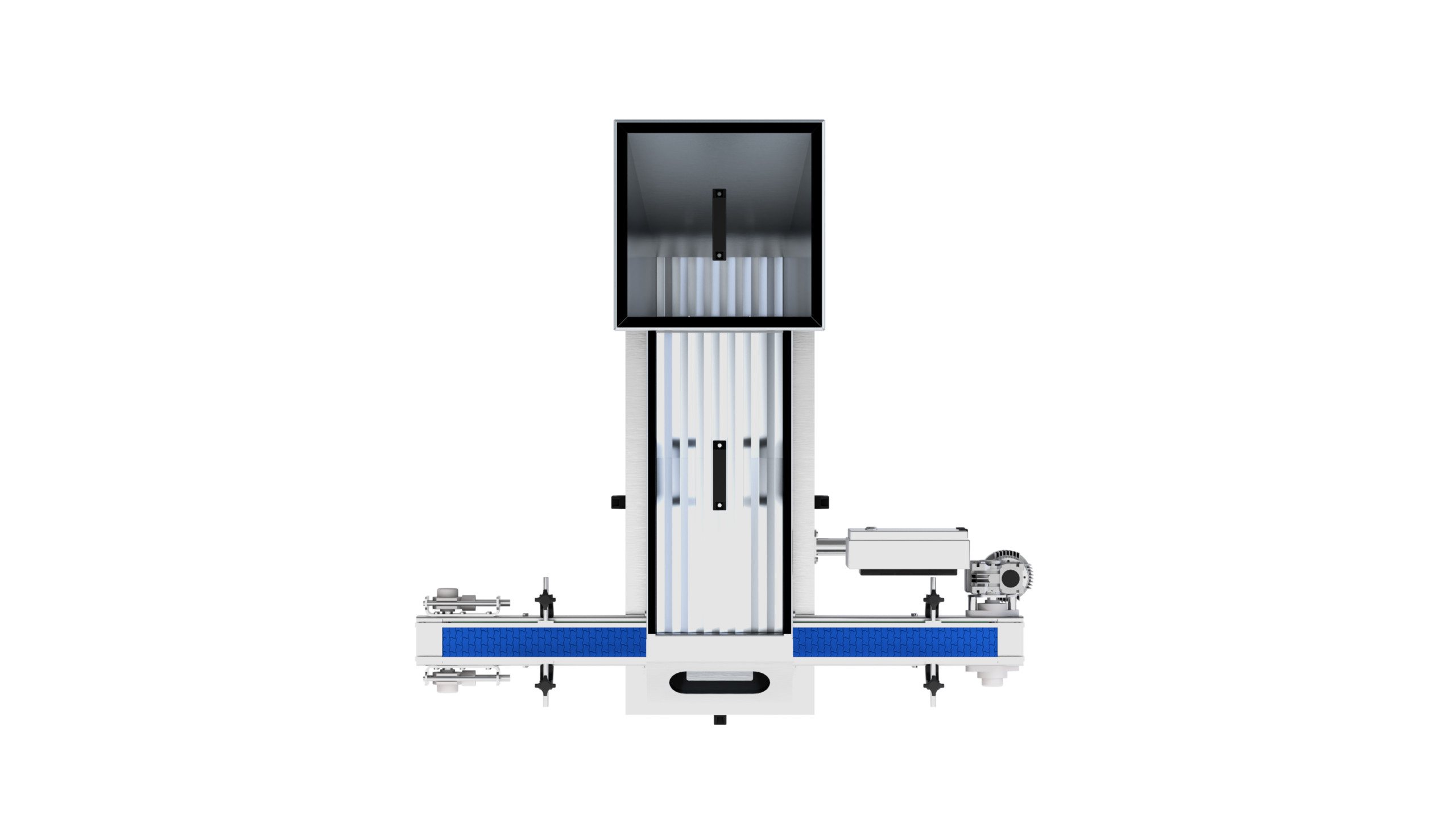

The conveyor-based linear tablet counting machine is an industrial solution developed by Türesan Engineering for the precise, rapid and controlled counting and packaging of products in tablet and capsule form. Thanks to its linear operating principle and vibration counting system, tablets of different sizes and shapes are ensured to move forward with a stable flow, while its multi-channel structure enables high-speed and repeatable counting performance.

Furthermore, counting methods specially developed for gummy products enable the accurate and reliable counting of sticky and elastic products without deformation.

The AISI 304 stainless steel chassis and AISI 316L stainless steel surfaces that come into contact with the product offer hygienic, durable, and safe use in accordance with hygiene standards for the food, pharmaceutical, and nutraceutical industries. With its large number of channels, nozzle structure that adapts to different bottle spacing, and high counting accuracy, the system easily adapts to variable production capacities.

With its design suitable for maximum tablet diameter, user-friendly control panel, and low maintenance requirements, the conveyor-based linear tablet counting machine is an ideal counting and filling solution for industrial production lines requiring high efficiency and process safety.