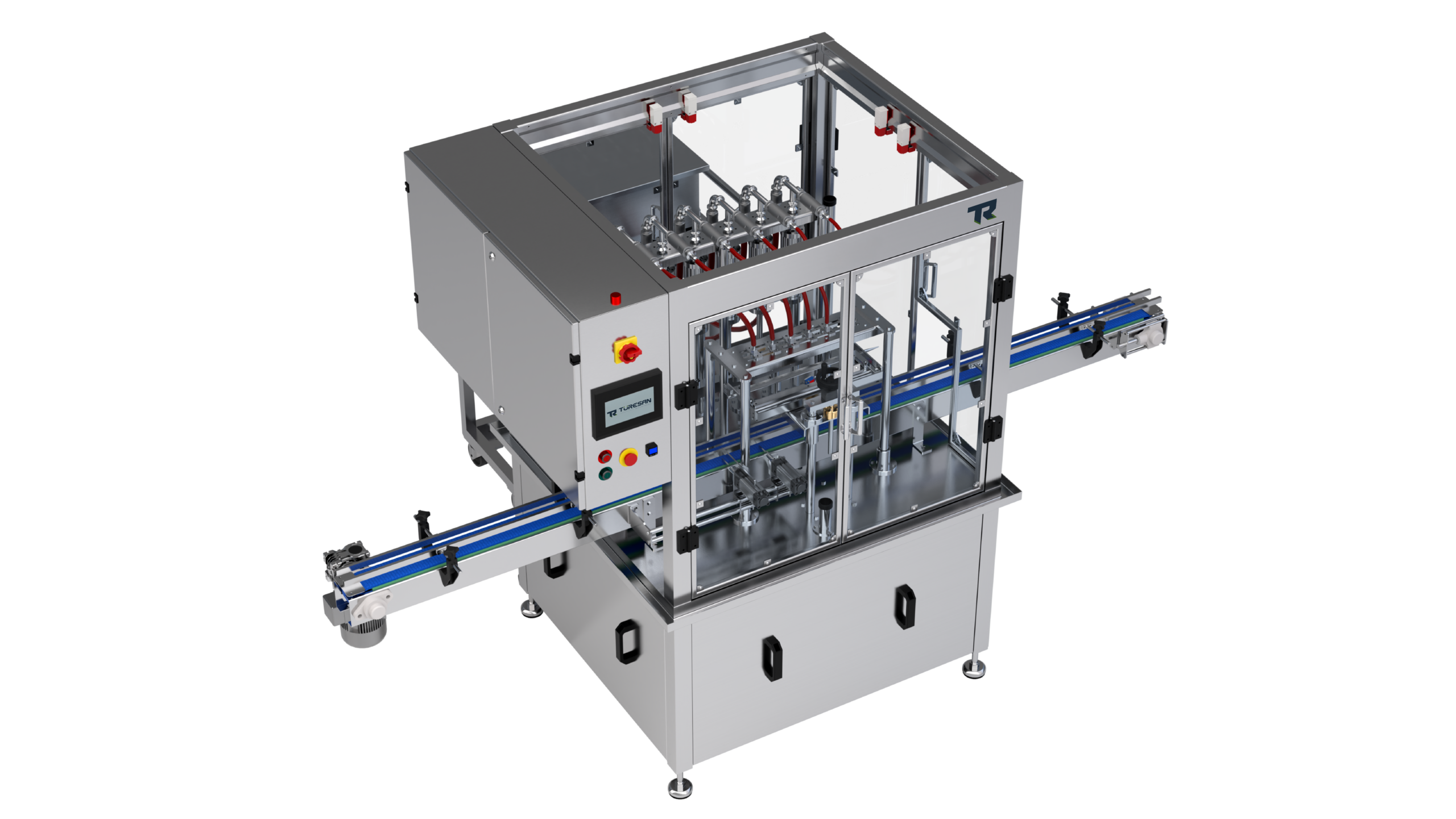

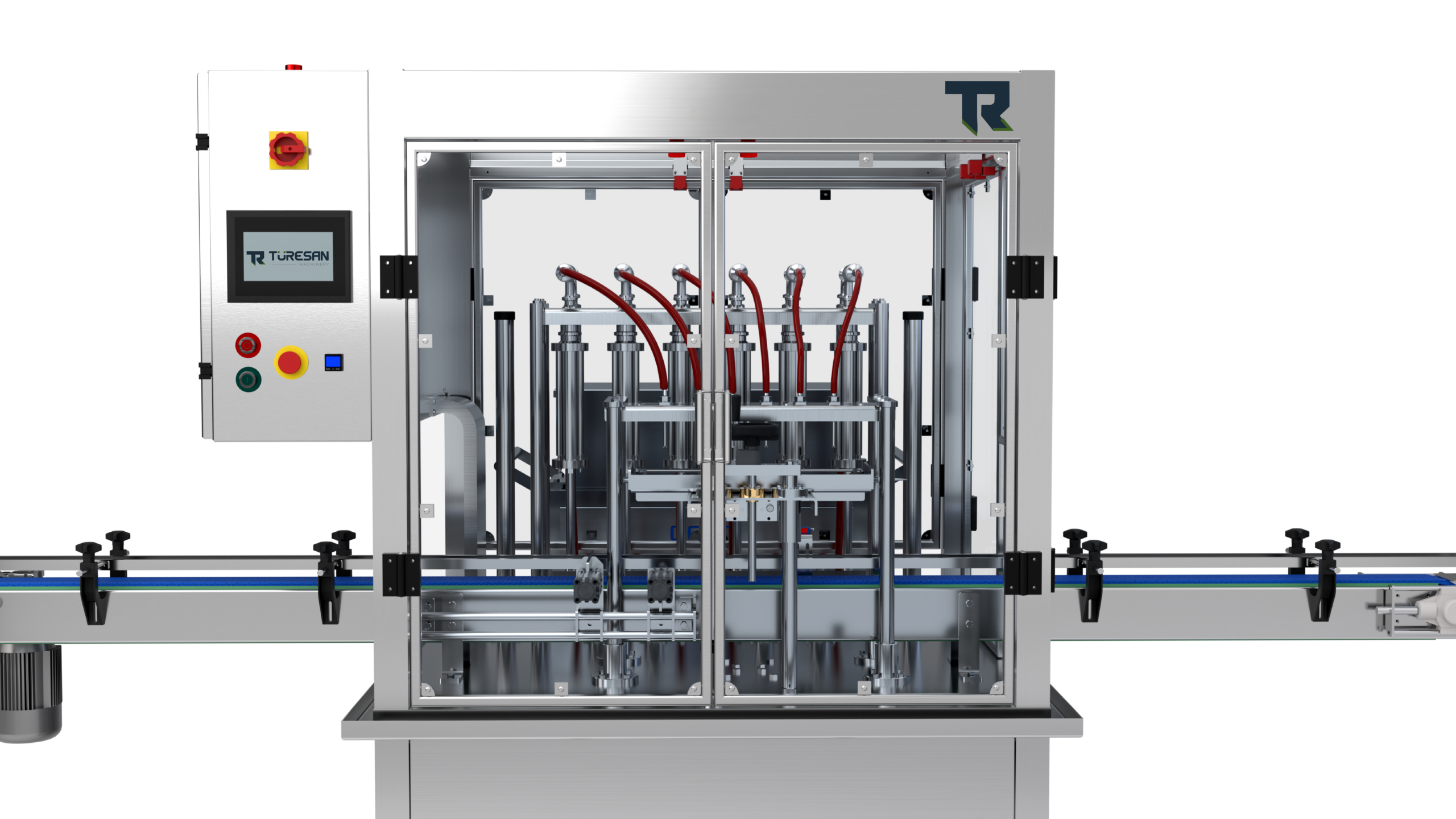

Conveyor System Linear Liquid Filling Machine

| Feature | Value |

|---|---|

| System | Linear |

| Filling System | Volumetric / Flowmeter / Load Cell / Level-Controlled |

| Base Frame | AISI 304 Stainless Steel Frame, Product-contact surfaces made of AISI 316L Stainless Steel |

| Balance Tank | Level-controlled, C.I.P. |

| Number of Nozzles | 1 – 12 |

| Filling Range | 20 – 300ml / 100 – 1000ml / 250 – 2500ml / 500 – 5000ml / 2000 – 20000ml |

| Filling Accuracy | ± %0,3 |

| Capacity | Varies depending on the bottle shape, number of nozzles, and product viscosity |

| Electrical Requirement | 380V, 50 Hz, 3 Phase |

| Air Requirement | 6-8 Bar Servo controlled nozzle movement speed and position adjustable via screen Servo Controlled Volumetric Filling System : Speed and weight adjustable via screen Inlet and Outlet Line Full Sensors |

Conveyor System Linear Liquid Filling Machine

The conveyor-based linear liquid filling machine is an industrial filling solution developed by Türesan Engineering to ensure the precise, rapid, and reliable filling of products with varying volumes and viscosities. Offering volumetric, flowmeter, load cell, and level-controlled filling options, it provides flexible solutions for the production needs of the food, chemical, and cosmetics industries.

The servo-controlled nozzle movement system, with speed and position adjustable from the screen, ensures precise adaptation to different packaging heights; while the servo-controlled volumetric filling system, with speed and weight adjustable via the operator panel, offers high filling accuracy and repeatability.

The AISI 304 stainless steel chassis and AISI 316L stainless steel surfaces that come into contact with the product ensure full compliance with hygiene standards while offering the advantage of long-term use. Its servo motor-driven structure increases filling accuracy, enabling stable and repeatable production performance.

Thanks to its modular design, which can accommodate different nozzle counts and a wide filling range, the system easily adapts to variable production capacities. Inlet and outlet line-full sensors continuously monitor product flow on the production line, increasing process safety. With its user-friendly control panel and low maintenance requirements, the conveyor-based linear liquid filling machine is an ideal industrial filling solution that increases business efficiency.