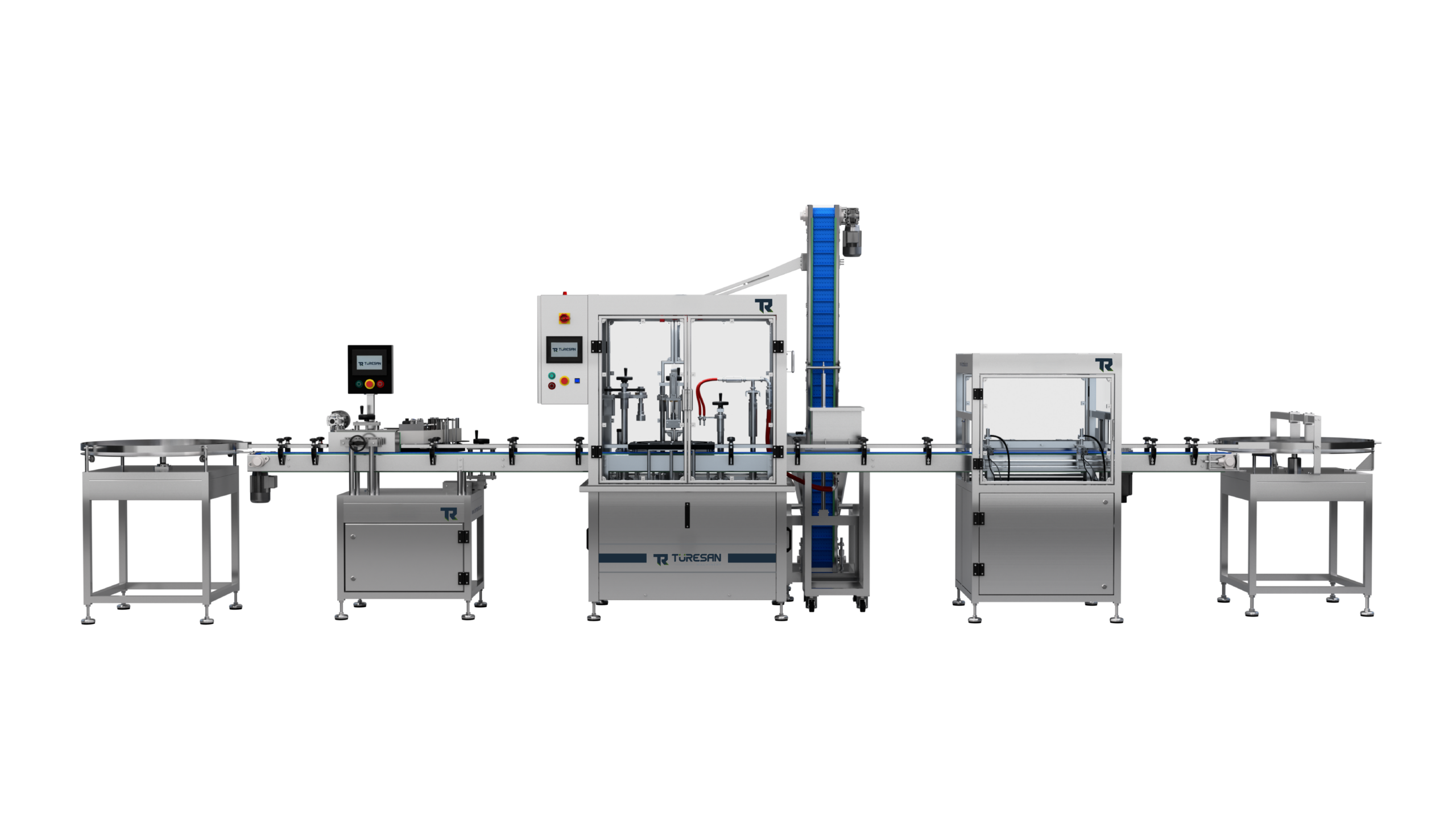

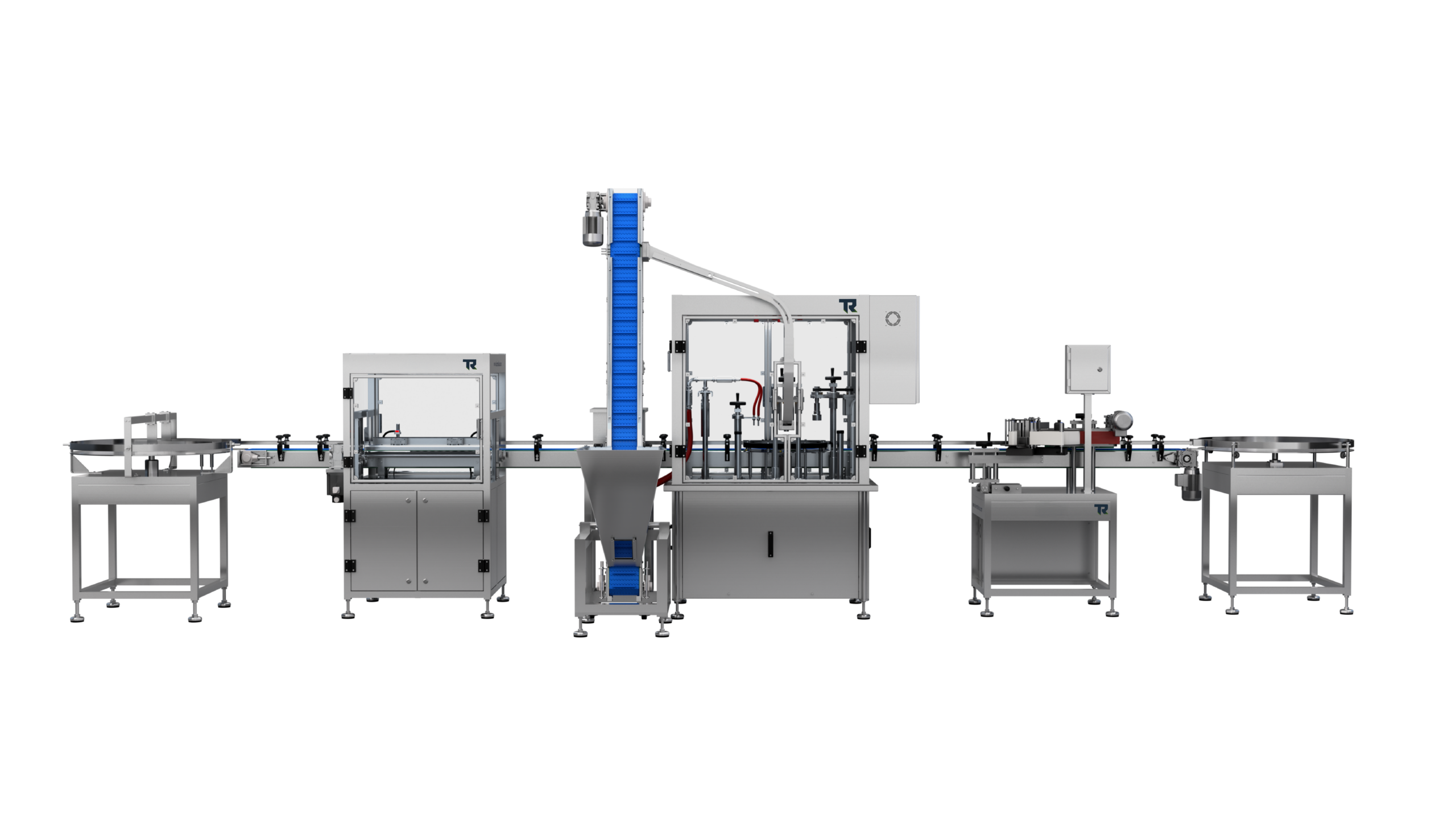

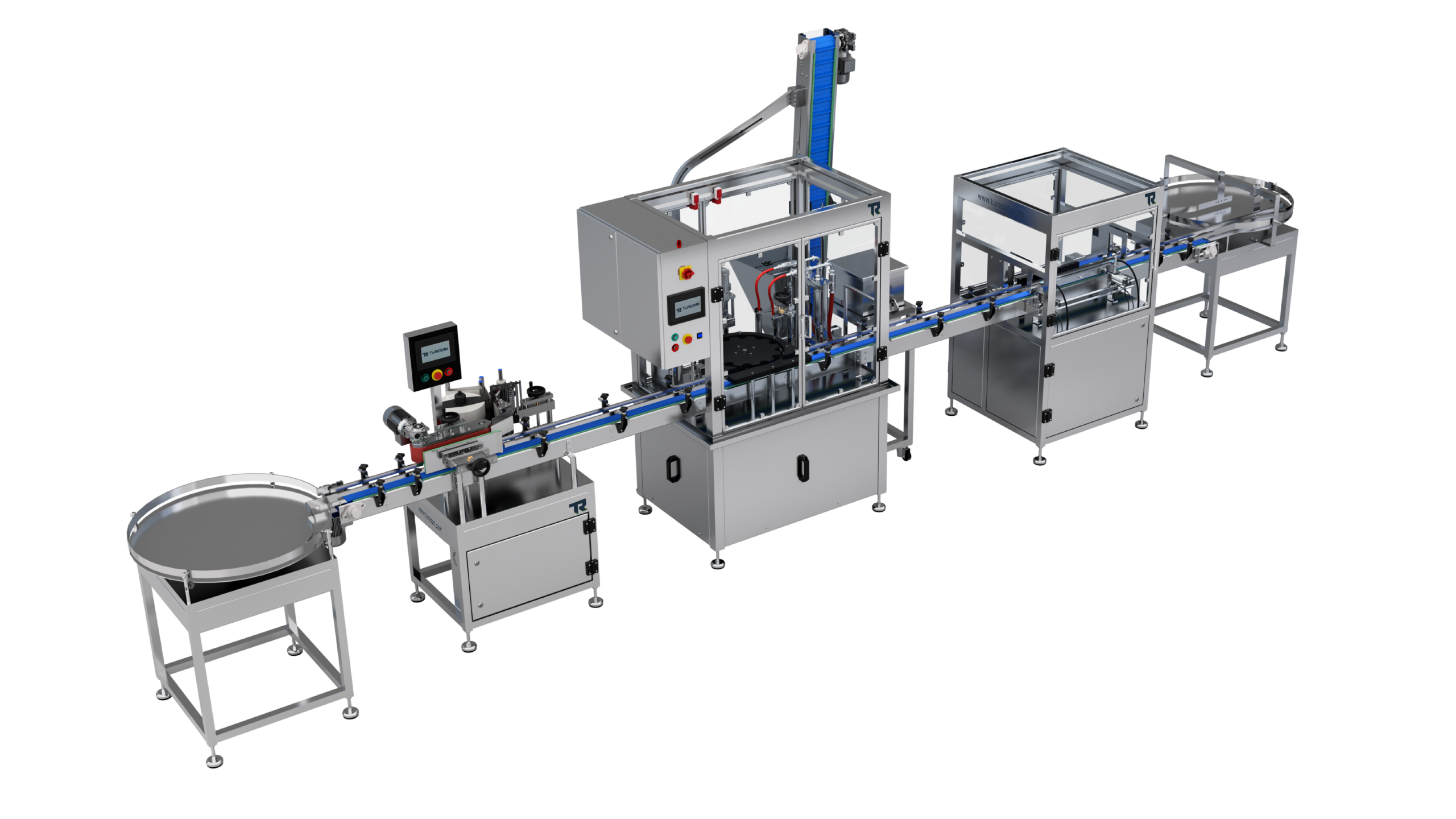

Conveyor System Rotary Liquid Filling Line

Bottle Cleaning Machine With Air

| Feature | Value |

|---|---|

| Construction | AISI 304 Stainless Steel Frame |

| Number of Nozzles | 1 – 12 |

| Air Quality | 0.12 Micron Filter and Ionizer |

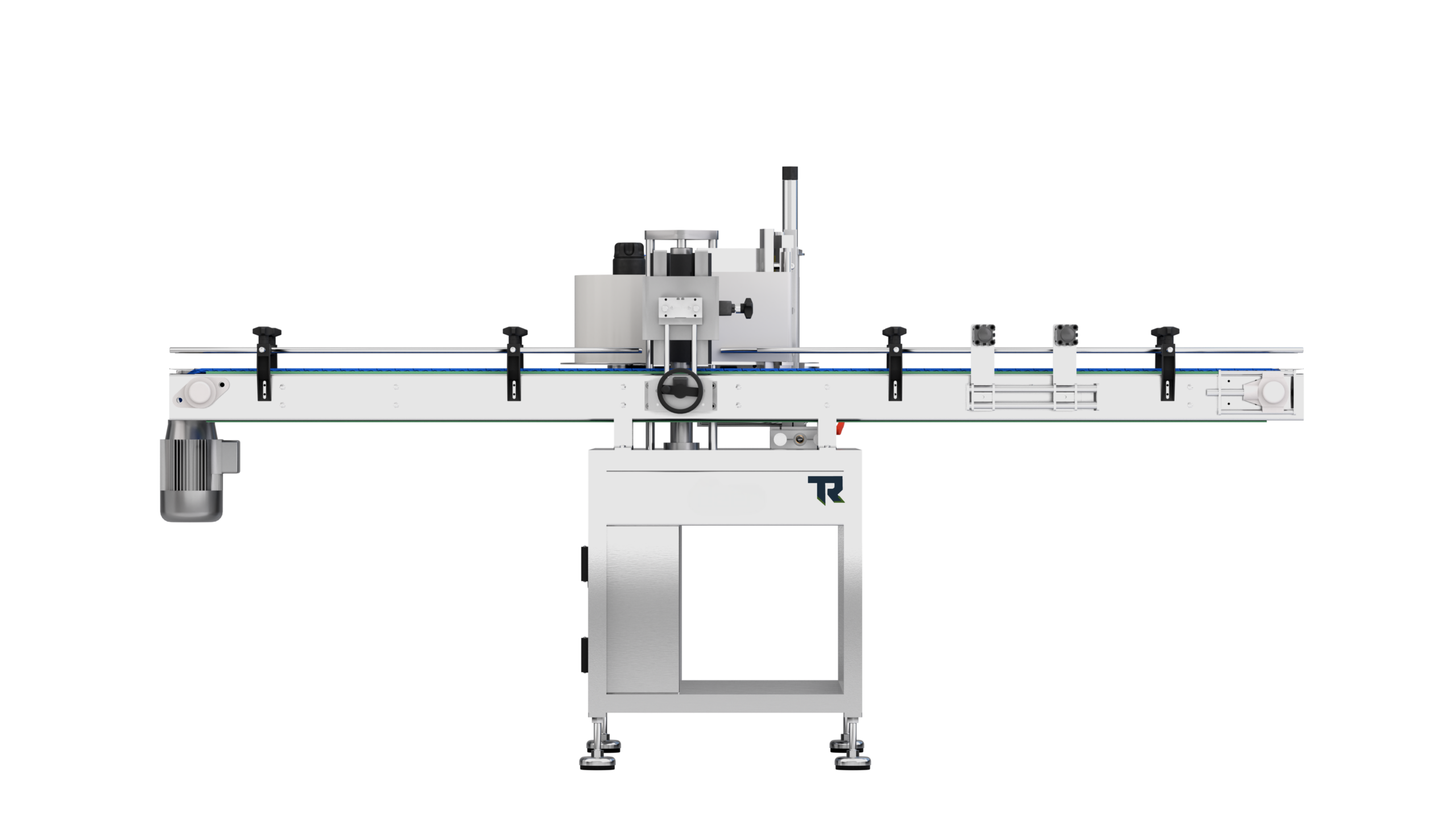

Labelling Machine

| Feature | Value |

|---|---|

| System | Linear / Rotary |

| Labelling Systems | Full Wrap Labeling / Single-Sided Labeling / Double-Sided Labeling / Bottom and Top Labeling |

| Applicator Options | Domestic / Imported |

Requirements for the Line

| Feature | Value |

|---|---|

| Electrical Requirements | 380V, 50 Hz, 3-phase |

| Air Requirements | 6-8 Bar |

Conveyor System Rotary Liquid Filling Machine

| Feature | Value |

|---|---|

| System | Rotary |

| Filling System | Volumetric/Flowmeter/Load Cell/Level Controlled |

| Construction | AISI 304 Stainless Steel Frame, Surfaces in contact with the product are AISI 316L Stainless Steel |

| Balance Tank | Level-Controlled AISI 316L |

| Number of Nozzles | 1-4 |

| Filling Range | 20 – 300ml / 100-1000ml / 250-2500ml |

| Filling Accuracy | ± %0,3 |

| Capacity | It is determined based on the bottle shape, number of nozzles, and product viscosity. |

| Capping Drive System | Servo Torque / Asynchronous Motor / Mechanical Torque / Air Motor |

| Capping System | Gripper / Three-Ball System / Pick&Place / Flat Clamping / Coating / Press |

| Cover Feeding | Elevator / Vibrating Bowl / Drum |

Conveyor System Rotary Liquid Filling Line

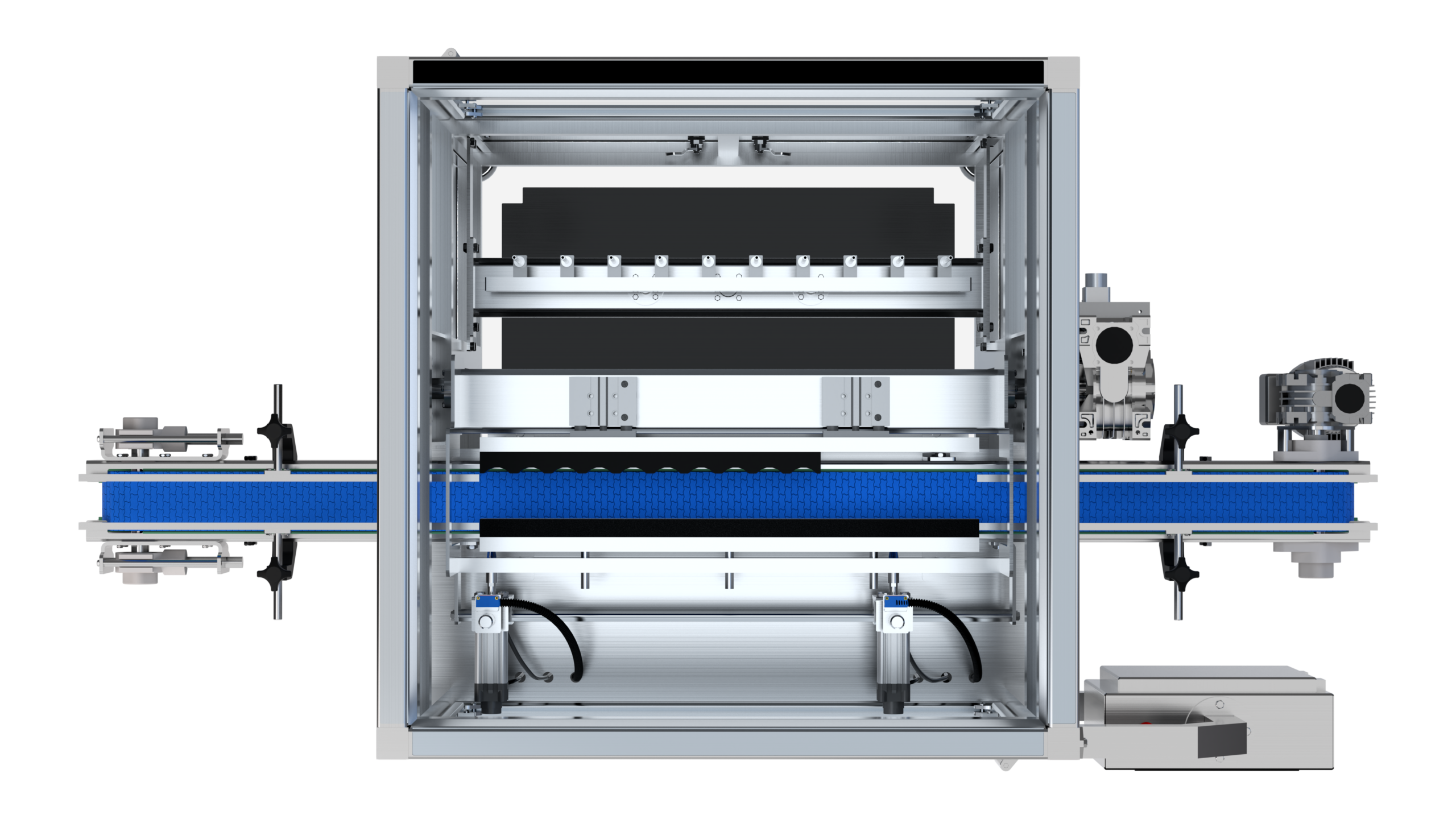

The conveyor rotary liquid filling line is an industrial solution developed for high-capacity filling lines that require continuous production. Thanks to its rotary system structure, filling, cap feeding, and cap sealing processes work in a synchronized manner, increasing production speed and efficiency. The filling and cap sealing units are located within the same chassis, giving the system a more compact structure and saving space in the production area.

The system, which offers flexible adaptation to different product viscosities and packaging types with volumetric, flowmeter, load cell, and level-controlled filling options, provides long-lasting and safe use that fully complies with the hygiene standards of the food, chemical, and cosmetic industries, thanks to its AISI 304 stainless steel frame and AISI 316L stainless steel surfaces that come into contact with the product.

Precise sealing is achieved for different cap types with servo-torque, mechanical-torque, or asynchronous motor-driven cap closure systems, while elevator, vibratory bowl, or drum cap feeding systems contribute to the continuous operation of the production line. The filling speed and position can be adjusted via the operator panel with servo-controlled nozzle movement, while the filling speed and weight values can be easily controlled thanks to the servo-controlled volumetric filling system. Inlet and outlet line full sensors optimize line flow and support production continuity.

With its modular design, user-friendly control panel, and low maintenance requirements, the rotary liquid filling machine offers a compact, efficient, and reliable filling solution for industrial production lines requiring high performance.

Which Products Do We Fill?

Sectors

Food & Beverage

Ayran, Cream Cheese, Yogurt, Honey, Chocolate, Jam, Cream, Olive Oil, Powdered Foods

Medicine

Supplements, Syrup, Nasal Spray, Throat Spray, Vitamins, Tablets, Powdered Medications

Cosmetics

Shampoo, Serum, Gel, Lotion, Body Oil, Cologne, Perfume, Cream, Natural Cosmetics

Chemistry

Vehicle Maintenance Products, Cleaning Products, Paint, Solution, Mineral Oil, Powdered Chemicals

Conveyor System Rotary Liquid Filling Line

Rotary Liquid Filling Machine with Conveyor System

Conveyor System Rotary Liquid Filling Machine

A filling system that maximizes liquid filling capacity with a reversible structure and increases efficiency by accelerating your production processes.

Labelling Machine

Labelling Machine

It is a machine that optimizes your production process by performing a fast and secure lid closing operation with a reversible system.

Bottle Cleaning Machine With Air

Bottle Cleaning Machine With Air

Cleaning the inside of bottles with air ensures hygiene before filling and increases quality and maximizes efficiency on your production line.-

Feeding Tray

Feeding Tray

It is a tray that optimizes the production process by ensuring the regular and continuous feeding of materials to the production line.

Collection Tray

Collection Tray

A tray that collects products coming off the production line in an orderly and safe manner, preparing them for packaging or subsequent processing.

Inkjet Coding

Inkjet Coding

The inkjet coding system is a coding solution that enables the fast and clear contactless printing of information such as production date, expiration date, batch number, and similar details onto products on the production line.

Check Weigher

Check Weigher

Check weigher is a quality control system that automatically checks the weight of products moving along the production line and separates products outside the tolerance range from the line.

Metal Detector

Metal Detector

A metal detector is a quality safety system that inspects products on the production line to detect any potential metal contaminants and ensures that contaminated products are removed from the line.

Reject Station

Reject Station

The reject station is a product diversion system that automatically separates products identified as defective by the control systems from the production line.