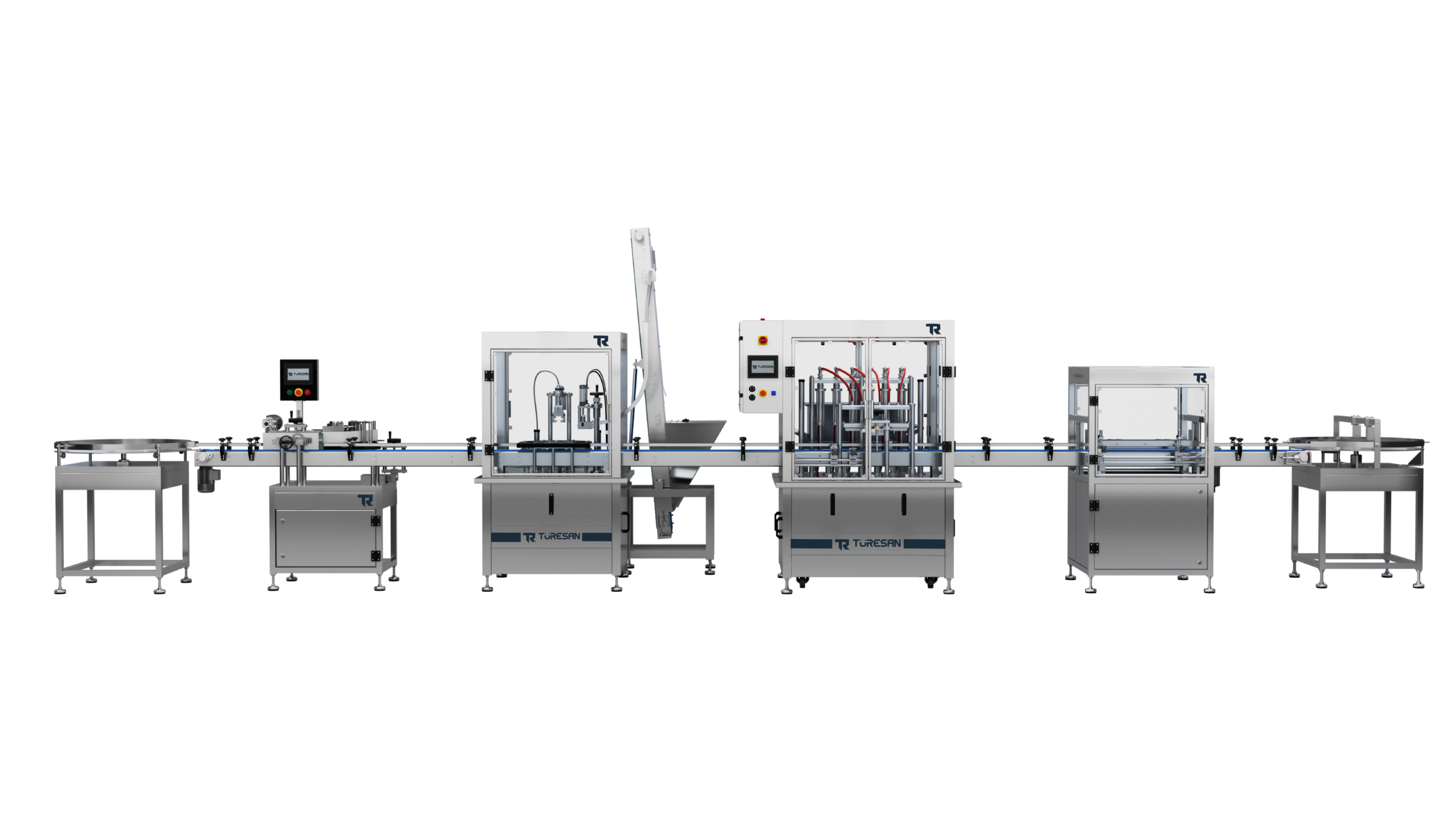

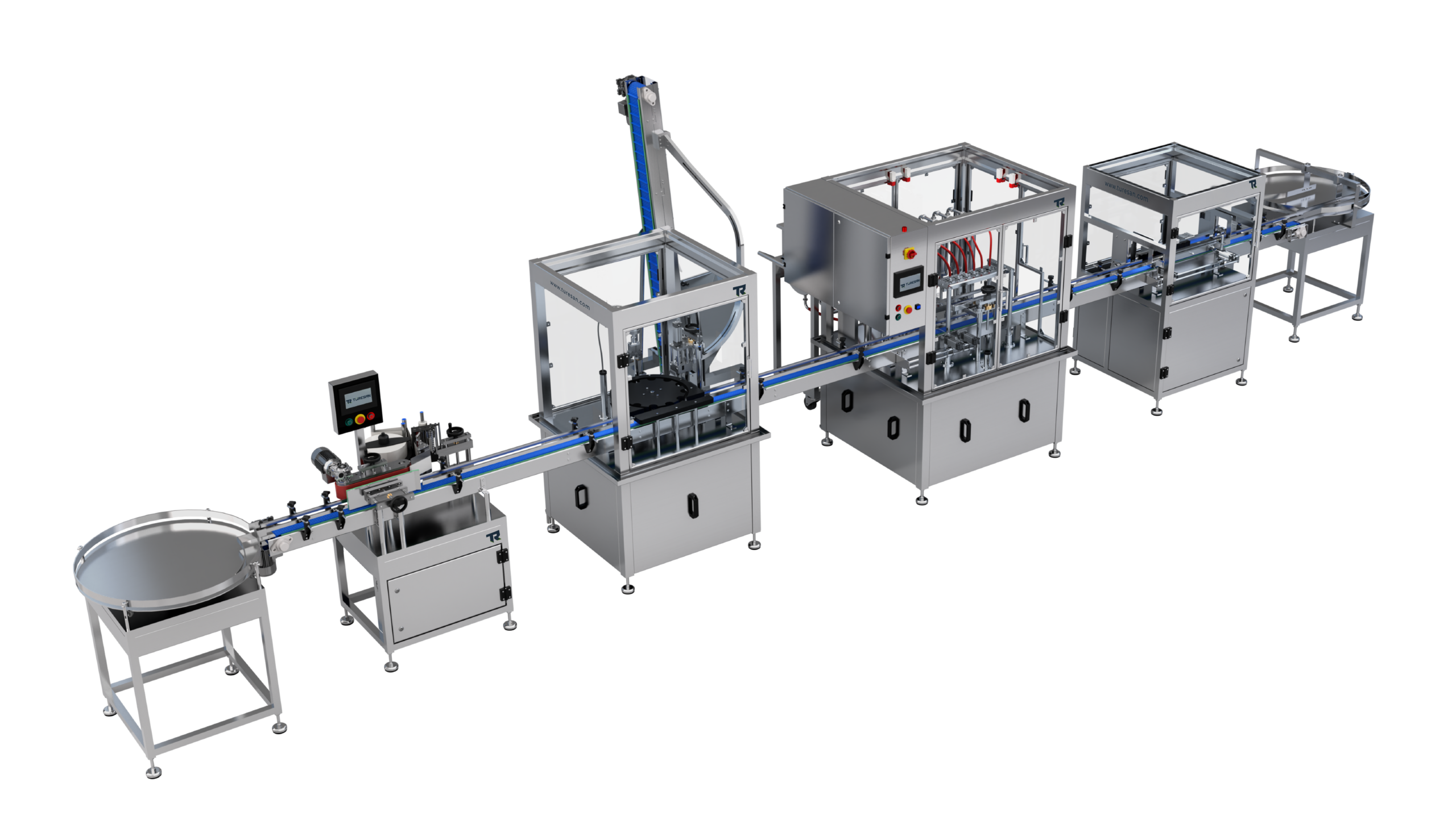

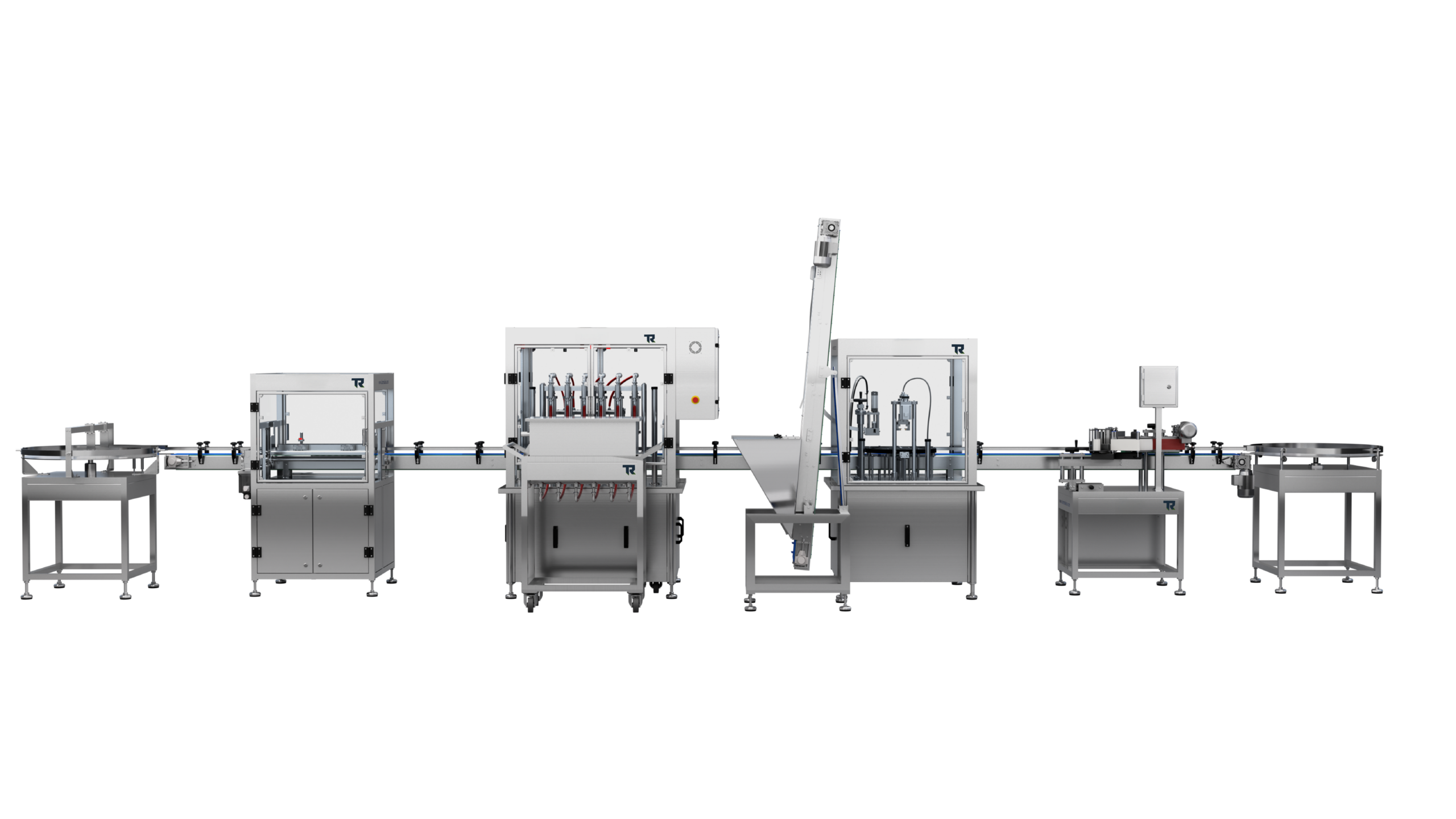

Conveyor System Linear Liquid Filling Line

Bottle Cleaning Machine With Air

| Feature | Value |

|---|---|

| Construction | AISI 304 Stainless Steel Frame |

| Number of Nozzles | 1 – 12 |

| Air Quality | 0.12 Micron Filter and Ionizer |

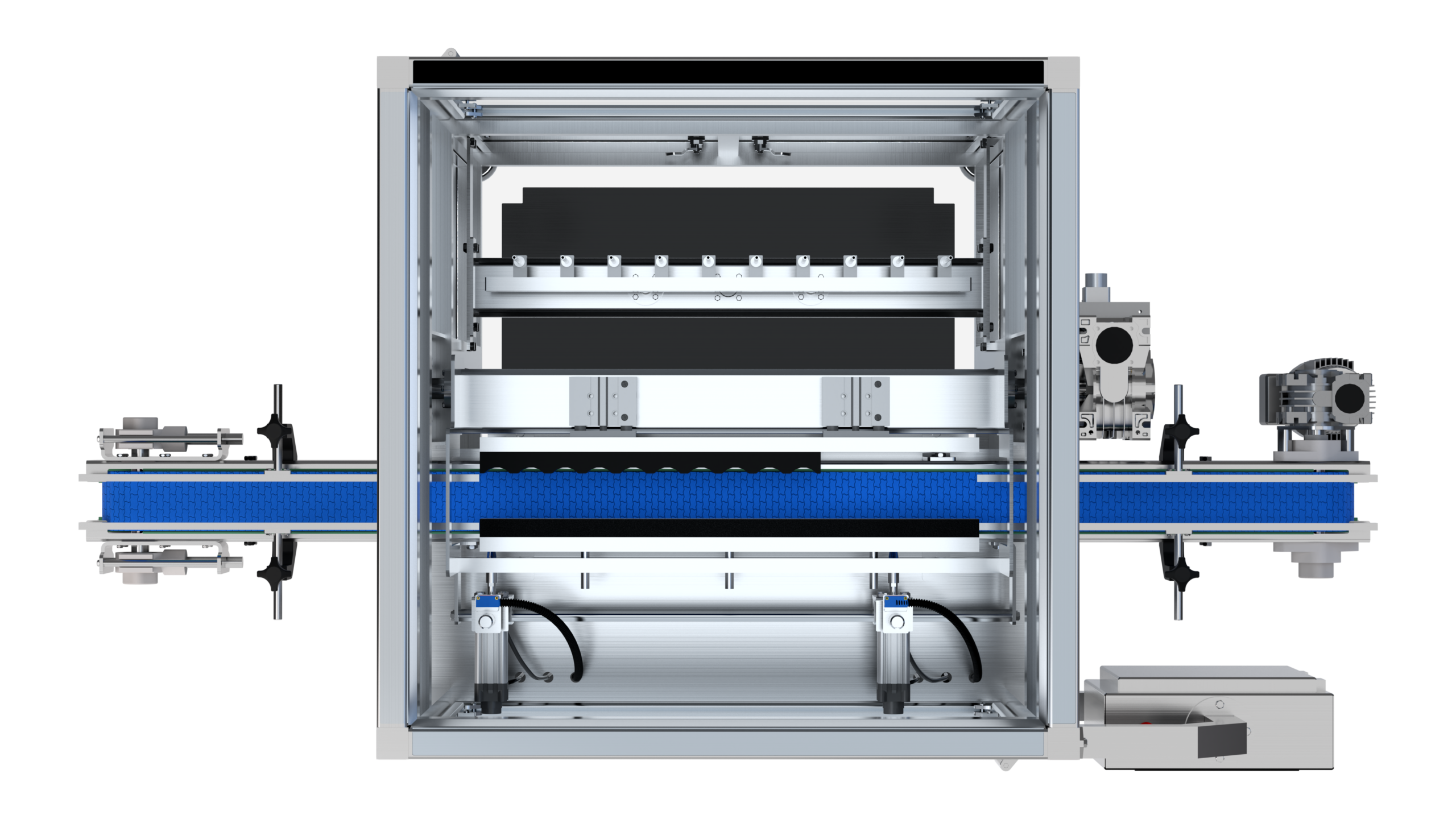

Conveyor System Linear Liquid Filling Machine

| Feature | Value |

|---|---|

| System | Linear |

| Filling System | Volumetric/Flowmeter/Load Cell/Level Controlled |

| Construction | AISI 304 Stainless Steel Frame, Surfaces in contact with the product are AISI 316L Stainless Steel |

| Balance Tank | Level-Controlled AISI 316L |

| Number of Nozzles | 1-12 |

| Filling Range | 20-300ml / 100-1000 ml / 250-2500 ml / 500-5000ml / 2000-20000ml/ 5000-30000ml |

| Filling Accuracy | ± %0,3 |

| Capacity | It is determined based on the bottle shape, number of nozzles, and product viscosity. |

Capping Machine

| Feature | Value |

|---|---|

| System | Linear / Rotary |

| Construction | AISI 304 Stainless Steel Frame, Surfaces in contact with the product are AISI 316L Stainless Steel |

| Lid Closing Drive System | Servo Torque / Asynchronous Motor / Mechanical Torque / Air Motor |

| Lid Closing System | Gripper / Three-Ball System / Pick&Place / Flat Clamping / Coating / Press |

| Cover Feeding | Elevator / Vibrating Bowl / Drum |

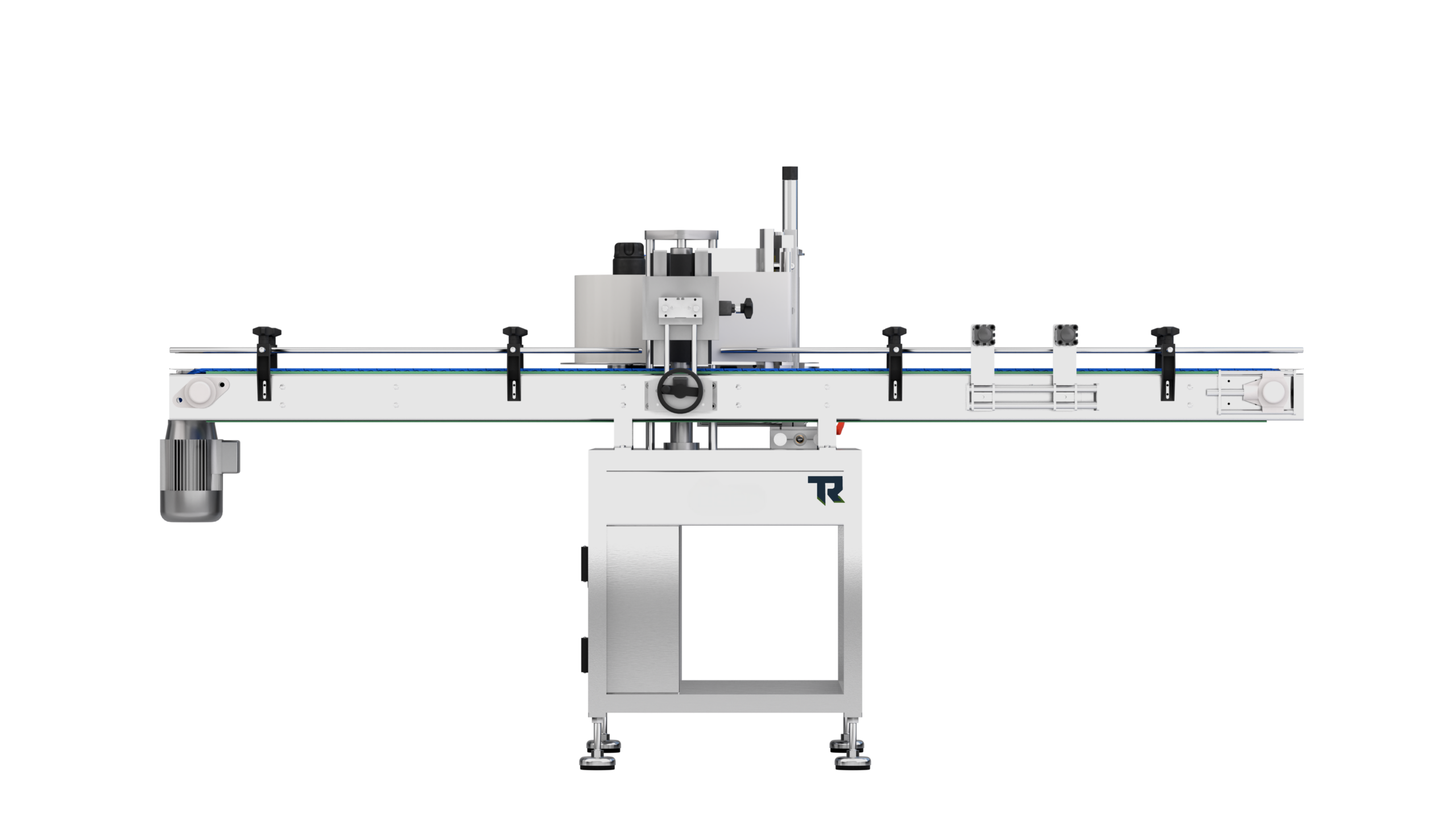

Labelling Machine

| Feature | Value |

|---|---|

| System | Linear / Rotary |

| Labelling Systems | Full Wrap Labelling / Single-Sided Labelling / Double-Sided Labelling / Bottom and Top Labelling |

| Applicator Options | Domestic / Imported |

Requirements for the Line

| Feature | Value |

|---|---|

| Electrical Requirements | 380V, 50 Hz, 3-phase |

| Air Requirements | 6-8 Bar |

Conveyor System Linear Liquid Filling Line

The conveyor linear liquid filling line is designed for the precise, fast, and hygienic filling of liquid products with varying volumes and viscosities. Thanks to its linear operating principle, packages moving along the conveyor are filled with high filling accuracy using volumetric, flowmeter, load cell, or level-controlled filling systems. The AISI 304 stainless steel frame and AISI 316 stainless steel construction used on surfaces in contact with the product ensure full compliance with hygiene standards in the food, cosmetics, chemical, and pharmaceutical industries. The level-controlled AISI 316L balance tank maintains product stability during filling, supporting uninterrupted production. The system offers flexible use from small bottles to high-volume packaging thanks to nozzle options ranging from 1 to 12 and a wide filling range, minimizing product losses with ±0.3% filling accuracy. Capacity may vary depending on bottle shape, nozzle count, and product viscosity, and the system can be easily integrated into existing production lines. Operating on a 380 V, 50 Hz, 3-phase electrical infrastructure and requiring 6–8 bar air pressure, the system provides a highly efficient and reliable industrial filling solution.

Which Products Do We Fill?

Sectors

Food & Beverage

Ayran, Cream Cheese, Yogurt, Honey, Chocolate, Jam, Cream, Olive Oil, Powdered Foods

Medicine

Supplements, Syrup, Nasal Spray, Throat Spray, Vitamins, Tablets, Powdered Medications

Cosmetics

Shampoo, Serum, Gel, Lotion, Body Oil, Cologne, Perfume, Cream, Natural Cosmetics

Chemistry

Vehicle Maintenance Products, Cleaning Products, Paint, Solution, Mineral Oil, Powdered Chemicals

Conveyor System Linear Liquid Filling Line

Conveyor System Linear Liquid Filling Machine

Conveyor System Linear Liquid Filling Machine

By filling liquids quickly and accurately with a linear system, it ensures maximum efficiency in filling processes.

Rotary System Capping Machine

Rotary System Capping Machine

It is a machine that optimizes your production process by performing a fast and secure lid closing operation with a reversible system.

Labelling Machine

Labelling Machine

It is a machine that adds speed and accuracy to your production process by quickly and accurately labeling your products with automatic labeling.

Bottle Cleaning Machine With Air

Bottle Cleaning Machine With Air

Cleaning the inside of bottles with air ensures hygiene before filling and increases quality and maximizes efficiency on your production line.

Feeding Tray

Feeding Tray

It is a tray that optimizes the production process by ensuring the regular and continuous feeding of materials to the production line.

Collection Tray

Collection Tray

A tray that collects products coming off the production line in an orderly and safe manner, preparing them for packaging or subsequent processing.

Inkjet Coding

Inkjet Coding

The inkjet coding system is a coding solution that enables the fast and clear contactless printing of information such as production date, expiration date, batch number, and similar details onto products on the production line.

Check Weigher

Check Weigher

Check weigher is a quality control system that automatically checks the weight of products moving along the production line and separates products outside the tolerance range from the line.

Metal Detector

Metal Detector

A metal detector is a quality safety system that inspects products on the production line to detect any potential metal contaminants and ensures that contaminated products are removed from the line.

Reject Station

Reject Station

The reject station is a product diversion system that automatically separates products identified as defective by the control systems from the production line.